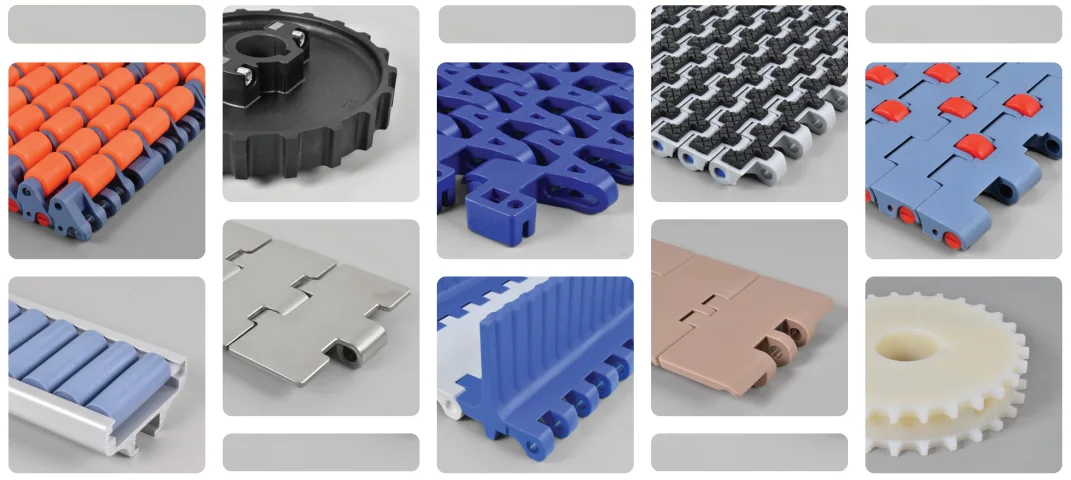

Product Description

Our Services

Product Design Material Selection

Mold Design Mold Making

Bulk Production Logo Printing

Surface Treatment Assembling

Packaging Door to Door Delivery

| Material | Nylon ,mc nylon, POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc. |

| Color | Black, white, red, green, transparent or any color according to Pantone code |

| Size | As per customer’s requirements |

| Technology | Injection molding, CNC machining, Extrusion |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

Detail Image

50+ types material of plastic, rubber, PU to help you perfectly adapt to the product application scenarios

Customize product features according to requirements:

1. Achieve medical-grade and food-grade products

2. Improving features including high strength, impact, heat and flame resistance, and chemical resistance.etc through various additives

3. Other appearances can achieve various customized services such as color, texture, hardness, pattern, and logo printing

4. Widely used in various industries: Automotive, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc.

Our products are widely used in various fields:

Why Choose Us

Our Machine

Product Range

Contact Us /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type E |

| Manufacturing Process: | Forging |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | Order Sample For sample price, package information, and logisti

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do plastic belts contribute to reducing friction and energy consumption in conveyor systems?

Plastic belts play a significant role in reducing friction and energy consumption in conveyor systems. Here’s a detailed explanation:

- Low Coefficient of Friction:

Plastic belts are engineered to have a low coefficient of friction, which means they offer minimal resistance to the movement of conveyed materials. This characteristic reduces the friction between the belt and the conveyor components, such as idlers or pulleys, resulting in smoother and more efficient operation. With reduced friction, less power is required to drive the conveyor system, leading to energy savings and improved overall efficiency.

- Lightweight Construction:

Plastic belts are generally lightweight compared to other belt materials, such as rubber or metal. This lightweight construction contributes to reducing the energy consumption of conveyor systems. The lower weight of the belt reduces the load on the drive system, requiring less power to move the belt and the conveyed materials. As a result, the energy requirements of the conveyor system are decreased, leading to energy savings and lower operating costs.

- Reduced Belt-to-Belt Friction:

In conveyor systems where multiple belts are used, plastic belts can help reduce belt-to-belt friction. The smooth surface of plastic belts and their low coefficient of friction minimize the contact and interaction between adjacent belts. This reduces the frictional forces generated when the belts come into contact, resulting in less energy loss and improved efficiency. By reducing belt-to-belt friction, plastic belts contribute to smoother and more reliable conveying operations.

- Improved Belt Flexibility:

Plastic belts are designed to be flexible, allowing them to adapt to the contours of conveyor systems more effectively. The flexibility of plastic belts helps to maintain proper belt alignment and reduces the occurrence of misalignment-related friction. When a belt is misaligned, it can cause increased friction and wear on the belt and the conveyor components, leading to higher energy consumption. By promoting better belt alignment, plastic belts minimize frictional losses and contribute to energy efficiency.

- Efficient Transfer of Power:

Plastic belts offer efficient power transfer within the conveyor system. The low coefficient of friction and lightweight construction of plastic belts allow for more effective transmission of power from the drive system to the belt. This efficient transfer of power ensures that a greater portion of the energy input is utilized for moving the conveyed materials, rather than being lost as heat or wasted due to friction. As a result, the overall energy consumption of the conveyor system is reduced.

In summary, plastic belts contribute to reducing friction and energy consumption in conveyor systems through their low coefficient of friction, lightweight construction, reduced belt-to-belt friction, improved belt flexibility, and efficient transfer of power. These characteristics not only enhance the overall efficiency of the conveyor system but also result in energy savings and reduced operating costs. By choosing plastic belts, industries can optimize their conveyor operations, minimize energy usage, and achieve more sustainable and cost-effective material handling processes.

What factors should be considered when selecting plastic belts for different industrial applications?

When selecting plastic belts for different industrial applications, several factors should be taken into consideration. Here are the key factors to consider:

- 1. Application Requirements:

Understand the specific requirements of the application. Consider factors such as the type of products being conveyed, the weight and size of the loads, the desired conveying speed, the operating temperature range, the presence of moisture or chemicals, and any special handling needs. Clear knowledge of the application requirements will help in selecting a plastic belt with the appropriate characteristics and capabilities.

- 2. Belt Configuration and Design:

Consider the belt configuration and design that best suits the application. Different plastic belts come in various configurations, including flat-top, flush-grid, raised-rib, and modular designs. Evaluate the belt’s surface texture, open area percentage, and any specialized features such as cleats, perforations, or vacuum capabilities. The belt design should align with the product characteristics, conveying conditions, and any specific requirements like incline/decline conveying or product diverting.

- 3. Material Selection:

Choose the appropriate plastic material for the belt based on the application’s demands. Common plastic materials used for belts include polyethylene (PE), polypropylene (PP), acetal (POM), polyvinyl chloride (PVC), and polyurethane (PU). Consider factors such as chemical resistance, temperature resistance, wear resistance, flexibility, and food-grade compliance. Ensure the selected material can withstand the operating conditions and environmental factors that the belt will encounter.

- 4. Load Capacity and Durability:

Evaluate the load capacity requirements of the application and select a plastic belt that can handle the intended loads. Consider the weight capacity per unit width and the overall strength and durability of the belt. Factors such as the belt’s tensile strength, impact resistance, and resistance to abrasion or wear are important for ensuring the longevity and reliability of the belt in demanding industrial environments.

- 5. Cleanability and Hygiene:

In industries with stringent hygiene requirements, such as food processing or pharmaceuticals, prioritize plastic belts that are easy to clean and sanitize. Look for belts with smooth, non-porous surfaces that resist bacterial growth and are compatible with regular washdown procedures. Consider whether the belt can withstand cleaning agents and temperature variations without degradation or compromising its hygienic properties.

- 6. Compatibility with Conveyor System:

Ensure the selected plastic belt is compatible with the existing or planned conveyor system. Consider factors such as the belt’s width and length options, the type of conveyor system (e.g., flatbed, roller, or modular), the compatibility of the belt’s sprockets or pulleys with the conveyor system, and the ease of installation and maintenance. Proper compatibility will ensure smooth integration and optimal performance of the belt within the conveyor system.

- 7. Cost and Long-Term Value:

Evaluate the cost-effectiveness and long-term value of the plastic belt. Consider not only the upfront cost of the belt but also its expected lifespan, maintenance requirements, and potential savings in terms of reduced downtime, increased productivity, and lower operational costs. Balancing cost considerations with the desired performance and durability will help in selecting a plastic belt that delivers the best value for the specific industrial application.

By considering these factors in the selection process, industries can choose the most suitable plastic belt that meets the unique requirements of their industrial applications, ensuring efficient and reliable material handling operations.

In what industries are plastic belts commonly employed for material handling?

Plastic belts are widely employed for material handling in various industries. Here’s a detailed explanation:

- 1. Food and Beverage Industry:

In the food and beverage industry, plastic belts are extensively used for material handling due to their hygienic properties, chemical resistance, and ease of cleaning. They are employed in applications such as conveying fruits, vegetables, baked goods, packaged foods, beverages, and dairy products. Plastic belts ensure safe and efficient transportation of food items while adhering to strict hygiene standards and preventing contamination.

- 2. Packaging and Logistics Industry:

Plastic belts find wide application in the packaging and logistics industry for the movement of packages, parcels, and containers. They are used in conveyor systems for sorting, merging, diverting, and accumulating packages during packaging, warehousing, and distribution processes. Plastic belts offer high strength, flexibility, and durability, allowing efficient handling of various package sizes and shapes.

- 3. Manufacturing and Assembly Industry:

In manufacturing and assembly processes, plastic belts are commonly employed for material handling tasks. They facilitate the transportation of components, parts, and products between different stages of production lines. Plastic belts can handle heavy loads, endure high-speed operations, and navigate through complex layouts, making them suitable for applications in automotive, electronics, appliances, and other manufacturing sectors.

- 4. Pharmaceutical and Healthcare Industry:

The pharmaceutical and healthcare industry relies on plastic belts for material handling in various stages of production, including drug manufacturing, packaging, and distribution. Plastic belts offer chemical resistance, easy cleanability, and compliance with industry regulations. They are used for conveying vials, bottles, blister packs, medical devices, and other pharmaceutical products in a controlled and hygienic environment.

- 5. E-commerce and Retail Industry:

Plastic belts play a vital role in the e-commerce and retail industry for material handling in distribution centers, fulfillment centers, and retail stores. They are used in conveyor systems for sorting, scanning, and transporting packages and products. Plastic belts offer smooth and reliable movement of items, facilitating efficient order fulfillment, inventory management, and store replenishment processes.

- 6. Automotive Industry:

In the automotive industry, plastic belts are employed for material handling tasks such as conveying automotive components, assemblies, and finished products. They are used in production lines for processes like painting, assembly, and testing. Plastic belts provide the necessary strength, flexibility, and wear resistance required to withstand the demanding conditions of automotive manufacturing.

These are just a few examples of the industries where plastic belts are commonly employed for material handling. Other industries such as textiles, electronics, agriculture, and mining also utilize plastic belts to streamline their material handling operations and improve overall efficiency.

editor by CX 2024-02-25

China high quality Cast Iron European Standard and American Standard V Belt Pulleys pulley attachments

Product Description

SPC 5Groove 1250mm Pitch 5050 Taper Bush large diameter v belt pulley

If your equipment requires high quality and precision pulley, we will be your best choice.

All sizes with different grooves are available.

| Europe Standard Types | SPZ-SPA-SPB-SPC |

| Bore | For Taper Bushings |

| Production Range |

Number Of Groove:1~10 Pitch Diameter:50-1250(mm) |

| Material | Cast Iron |

| Finish | Black Phosphate,Plastic Coating |

| American standards Standard Types | A-B-C-D | 3V-5V-8V |

| Typcal Series | AL,AK,BK,TB,B,TC,C,D | 3V,5V,8V |

| Bore | Straight | Straight |

| For Tarer Bushings | For Taper Bushings | |

| For QD Bushings | For QD Bushings | |

| Production Range |

Number Of Groove:1~12 | Number Of Groove:1~12 |

| Outer Diameter:3.4~58.0(Inch) | Outer Diameter:2.2~71.0(Inch) | |

| Material | Cast Iron | |

| Finish | Black Phosphate,Plastic Coating | |

Please consult us for any products unlisted here.

Lead Time

| Quantity(Pieces) | 1 – 50 | 51 – 100 | 101 – 500 | >500 |

| Est. Time(days) | 15 | 30 | 50 | To be negotiated |

Each pulley is strictly static balanced with high precision machining tools. Unbalanced volume will corrected accurated.

Company Information

MIGHTY, a brand belongs to SCMC Corp. which is a wholly state-owned enterprise established in 1980, is specialized in producing precision mechanical power transmission products. After years of hard work, Mighty has already got the certificate of ISO9001:2000 and become a holding company of 3 manufacturing factories.

Mighty’s products are mainly exported to Europe, America and Middle East market. With the top-ranking management, professional technical support and abundant export experience, Mighty has established lasting and stable business partnership with many world famous companies and has got good reputation from CZPT customers in international sales.

Equipment: sawing machine, CNC Lathe, drilling machine, hobbing machine, punch machine, milling machine, gear shaper, grinding machine, machining center, etc.

Trade Show: PTC Asia, Canton Fair, Hannover Messe, IFPE

Main Products:

Timing belt pulleys, timing bars, timing belt clamping plates.

Locking elements and shrink discs: could be alternative for Ringfeder, Sati, Chiaravalli, BEA, KBK, Tollok, etc.

V belt pulleys and taper lock bush.

Sprockets, idler, and plate wheels.

Gears and racks: spur gear, helical gear, bevel gear, worm gear, gear rack.

Shaft couplings: miniature coupling, curved tooth coupling, chain coupling, HRC coupling, normex coupling, FCL coupling, GE coupling, rigid and flexible coupling, jaw coupling, disc coupling, multi-beam coupling, universal joint, torque limiter, shaft collars.

Forging, Casting, Stamping Parts.

Other customized power transmission products and Machining Parts (OEM).

Application

1. Engineering: machine tools, foundry equipments, conveyors, compressors, painting systems, etc.

2. Pharmaceuticals& Food Processing: pulp mill blowers, conveyor in warehouse, agitators, grain, boiler, bakery machine, labeling machine, robots, etc.

3. Agriculture Industries: cultivator, rice winnower tractor, harvester, rice planter, farm equipment, etc.

4. Texitile Mills: looms, spinning, wrappers, high-speed auto looms, processing machine, twister, carding machine, ruler calendar machine, high speed winder, etc.

5. Printing Machinery: newspaper press, rotary machine, screen printer machine, linotype machine offset printer, etc.

6. Paper Industries: chipper roll grinder, cut off saw, edgers, flotation cell and chips saws, etc.

7. Building Construction Machinery: buffers, elevator floor polisher mixing machine, vibrator, hoists, crusher, etc.

8. Office Equipments: typewriter, plotters, camera, money drive, money sorting machine, data storage equipment, etc.

9. Glass and Plastic Industries: conveyor, carton sealers, grinders, creeper paper manufacturing machine, lintec backing, etc.

10. Home Appliances: vacuum cleaner, laundry machine, icecream machine, sewing machine, kitchen equipments, etc.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contacts

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit. To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

Any question or inquiry, pls contact us without hesitate, we assure any of your inquiry will get our prompt attention and reply!

| Certification: | ISO |

|---|---|

| Pulley Sizes: | Type A |

| Manufacturing Process: | Casting |

| Material: | Iron |

| Surface Treatment: | Polishing |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 0.01/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

The importance of pulleys

A pulley is a wheel that rides on an axle or axle. The purpose of the pulley is to change the direction of the tensioning cable. The cable then transfers the power from the shaft to the pulley. This article explains the importance of pulleys and demonstrates several different uses for this machine. Also, see the Mechanical Advantages section below for the different types. let’s start.

simple machine

A simple pulley machine is a device used to transfer energy. It consists of a wheel with flexible material on the rim and a rope or chain tied to the other end. Then lift the load using the force applied to the other end. The mechanical advantage of this system is one, as the force applied to the load is the same as the force on the pulley shaft.

A simple pulley machine has many benefits, from the ability to build pyramids to building modern buildings with it. Pulleys are also popular with children because they can perform simple tasks such as lifting toys onto a slide, sliding them off the slide, and lifting them up again. These activities, called “transportation” by child development theorists, allow them to learn about the physics of simple machines in the process.

The mechanism works by using cables to transmit force. The cable is attached to one side of the pulley and the other side is pulled by the user. Lift the load by pulling on one end and the other end of the rope. Simple pulley machines have many commercial and everyday applications, including helping move large objects. They can be fixed or movable, and can be a combination of both. The present invention is a great tool for any beginner or engineer.

axis

The axle wheel is the basic mechanical part that amplifies the force. It may have originally appeared as a tool to lift buckets or heavy objects from a well. Its operation is demonstrated by large and small gears attached to the same shaft. When applied to an object, the force on the large gear F overcomes the force W on the pinion R. The ratio of these two forces is called the mechanical advantage.

The ideal mechanical advantage of shaft pulleys is their radius ratio. A large radius will result in a higher mechanical advantage than a small radius. A pulley is a wheel through which a rope or belt runs. Often the wheels are interconnected with cables or belts for added mechanical advantage. The number of support ropes depends on the desired mechanical advantage of the pulley.

In the design of the axle wheel, the axle is the fulcrum and the outer edge is the handle. In simple terms, wheels and axle pulleys are improved versions of levers. The axle pulley moves the load farther than the lever and connects to the load at the center of the axle. Shaft pulleys are versatile and widely used in construction.

rope or belt

Ropes or pulleys are mechanical devices used to move large masses. The rope supports a large mass and can be moved easily by applying a force equal to one quarter of the mass to the loose end. Quad pulleys have four wheels and provide the mechanical advantage of four wheels. It is often used in factories and workshops. It is also a popular choice in the construction industry. If you are installing a pulley in your vehicle, be sure to follow these simple installation instructions.

First, you need to understand the basics of how a rope or pulley works. The machine consists of one or more wheels that rotate on an axle. The rope or belt is wrapped around the pulley and the force exerted on the rope is spread around the pulley. It then transfers the force from one end of the rope to the other. The pulley system also helps reduce the force required to lift objects.

Another common rope or pulley is the differential pulley. This is similar to a rope pulley, but consists of two pulleys of different radii. The tension in the two halves of the rope supports half the load that the live pulley should carry. These two different types of pulleys are often used together in composite pulley systems.

Mechanical advantage

The mechanical advantage is the ratio of the force used to move the load through the pulley system to the force applied. It has been used to measure the effectiveness of pulley systems, but it also requires assumptions about applied forces and weights. In a simple 1:1 pulley system, the weight lifting the weight is the same as the weight of the person pulling the weight. Adding mechanical advantage can help make up for the lack of manpower.

This advantage stems from the mechanical properties of simple machines. It requires less force and takes up less space and time to accomplish the same task. The same effect can also be achieved by applying less force at a distance. Furthermore, this effect is called the output force ratio. The basic working principle of a pulley system is a rope with a fixed point at one end. The movable pulley can be moved with very little force to achieve the desired effect.

The load can be moved through the vertical entry using a simple pulley system. It can use a simple “pulley block” system with a 2:1 “ladder frame” or a 4:1 with dual pulleys. This can be combined with another simple pulley system to create a compound pulley system. In this case, a simple pulley system is pulling another pulley, giving it a 9:1 mechanical advantage.

Commonly used

You’ve probably seen pulley systems in your kitchen or laundry room. You probably already use it to hang clothes on an adjustable clothesline. You may have seen motor pulleys in the kitchens of commercial buildings. You might even have seen one on a crane. These machines use a pulley system to help them lift heavy loads. The same goes for theaters. Some pulleys are attached to the sides of the stage, enabling the operator to move up and down the stage.

Pulley systems have many uses in the oil and petroleum industry. For example, in the oil and gas industry, pulley systems are used to lay cables. They are arranged in a pulley structure to provide mechanical energy. When the rope is running, two pulleys are hung on the derrick to facilitate smooth running. In these applications, pulleys are very effective in lifting heavy objects.

A pulley is a simple mechanical device that converts mechanical energy into motion. Unlike chains, pulleys are designed to transfer power from one location to another. The force required to lift an object with a pulley is the same as that required by hand. It takes the same amount of force to lift a bucket of water, but it’s more comfortable to pull sideways. A bucket of water weighs the same as when lifted vertically, so it’s easy to see how this mechanism can be useful.

Safety Notice

When using pulleys, you should take several safety precautions to keep your employees and other workers on the job site safe. In addition to wearing a hard hat, you should also wear gloves to protect your hands. Using pulleys can lead to a variety of injuries, so it’s important to keep these precautions in mind before using pulleys. Here are some of the most common:

Pulleys are an important piece of equipment to have on hand when lifting heavy objects. Pulleys not only reduce the force required to lift an object, but also the direction of the force. This is especially important if you are lifting heavy objects, such as a lawn mower or motorcycle. Before starting, it is important to make sure that the anchoring system can support the full weight of the object you are lifting.

When using a pulley system, make sure the anchor points are adequate to support the load. Check with the pulley manufacturer to determine the weight it can safely lift. If the load is too large, composite pulleys can be used instead. For vertical lifts, you should use a sprocket set and wear personal protective equipment. Safety precautions when using pulleys are critical to worker health and safety.

editor by CX

2023-06-05

China OEM Factory Direct Cast Iron Agricultural Machinery Spare Parts V Belt Wheel Pulleys near me manufacturer

Product Description

We are a foundry for casting processed products.

With more than 10 years of experience, our products have been exported to the United States, Germany, Italy, Spain, etc.

Our engineers have more than 10 years experience in quality control and can guarantee the highest quality of castings

A factory that integrates casting, heat treatment, and machining capabilities to achieve lower costs

| Process | Shell Model Casting,Heat treatment,CNC machining, |

| Equipment | Semi automatic casting line.CNC centers, CNC turning, CNC lathes, line cutting, milling, drilling, grinding |

| Material | ASTM (60-40-18,65-45-12,70-50-05,80-60-03,100-70-03).ect. |

| Surface | Trimming, Deburring,Polishing, Shot blasting, Sand blasting,Tumbling, Powder coating, Anodizing, Chrome, Zinc, Electrophoresis, |

| Software Assistance | Pro-e/Solid work/UG/Auto CAD |

| Products Application | Auto Parts, Agricultural Machinery Parts, Power Parts, Railway Machinery Parts, Construction Machinery Parts, Elevator Parts.ect. |

| Process | Shell Model Casting,Heat treatment,CNC machining, |

| Equipment | Semi automatic casting line.CNC centers, CNC turning, CNC lathes, line cutting, milling, drilling, grinding |

| Material | ASTM (60-40-18,65-45-12,70-50-05,80-60-03,100-70-03).ect. |

| Surface | Trimming, Deburring,Polishing, Shot blasting, Sand blasting,Tumbling, Powder coating, Anodizing, Chrome, Zinc, Electrophoresis, |

| Software Assistance | Pro-e/Solid work/UG/Auto CAD |

| Products Application | Auto Parts, Agricultural Machinery Parts, Power Parts, Railway Machinery Parts, Construction Machinery Parts, Elevator Parts.ect. |

How to use the pulley system

Using a pulley system is a great way to move things around your home, but how do you use a pulley system? Let’s look at the basic equations that describe a pulley system, the types of pulleys, and some safety considerations when using pulleys. Here are some examples. Don’t worry, you’ll find all the information you need in one place!

Basic equations of pulley systems

The pulley system consists of pulleys and chords. When the weight of the load is pulled through the rope, it slides through the groove and ends up on the other side. When the weight moves, the applied force must travel nx distance. The distance is in meters. If there are four pulleys, the distance the rope will travel will be 2×24. If there are n pulleys, the distance traveled by the weight will be 2n – 1.

The mechanical advantage of the pulley system increases with distance. The greater the distance over which the force is applied, the greater the leverage of the system. For example, if a set of pulleys is used to lift the load, one should be attached to the load and the other to the stand. The load itself does not move. Therefore, the distance between the blocks must be shortened, and the length of the line circulating between the pulleys must be shortened.

Another way to think about the acceleration of a pulley system is to think of ropes and ropes as massless and frictionless. Assuming the rope and pulley are massless, they should have the same magnitude and direction of motion. However, in this case the quality of the string is a variable that is not overdone. Therefore, the tension vector on the block is labeled with the same variable name as the pulley.

The calculation of the pulley system is relatively simple. Five mechanical advantages of the pulley system can be found. This is because the number of ropes supporting the load is equal to the force exerted on the ropes. When the ropes all move in the same direction, they have two mechanical advantages. Alternatively, you can use a combination of movable and fixed pulleys to reduce the force.

When calculating forces in a pulley system, you can use Newton’s laws of motion. Newton’s second law deals with acceleration and force. The fourth law tells us that tension and gravity are in equilibrium. This is useful if you need to lift heavy objects. The laws of motion help with calculations and can help you better understand pulley systems.

Types of pulleys

Different types of pulleys are commonly used for various purposes, including lifting. Some pulleys are flexible, which means they can move freely around a central axis and can change the direction of force. Some are fixed, such as hinges, and are usually used for heavier loads. Others are movable, such as coiled ropes. Whatever the purpose, pulleys are very useful in raising and lowering objects.

Pulleys are common in many different applications, from elevators and cargo lift systems to lights and curtains. They are also used in sewing machine motors and sliding doors. Garage and patio doors are often equipped with pulleys. Rock climbers use a pulley system to climb rocks safely. These pulley systems have different types of pinions that allow them to balance weight and force direction.

The most common type of pulley is the pulley pulley system. The pulley system utilizes mechanical advantages to lift weight. Archimedes is thought to have discovered the pulley around 250 BC. in ancient Sicily. Mesopotamians also used pulleys, they used ropes to lift water and windmills. Pulley systems can even be found at Stonehenge.

Another type of pulley is called a compound pulley. It consists of a set of parallel pulleys that increase the force required to move large objects. This type is most commonly used in rock climbing and sailing, while composite pulleys can also be found in theater curtains. If you’re wondering the difference between these two types of pulleys, here’s a quick overview:

Mechanical Advantages of Pulley Systems

Pulley systems offer significant mechanical advantages. The ability of the system to reduce the effort required to lift weights increases with the number of rope loops. This advantage is proportional to the number of loops in the system. If the rope had only one loop, then a single weight would require the same amount of force to pull. But by adding extra cycles, the force required will be reduced.

The pulley system has the advantage of changing the direction of the force. This makes it easier to move heavy objects. They come in both fixed and mobile. Pulleys are used in many engineering applications because they can be combined with other mechanisms. If you want to know what a pulley can do, read on! Here are some examples. Therefore, you will understand how they are used in engineering.

Single-acting pulleys do not change direction, but compound pulleys do. Their mechanical advantage is six. The compound pulley system consists of a movable pulley and a fixed pulley. The mechanical advantage of the pulley system increases as the number of movable wheels decreases. So if you have two wheels, you need twice as much force to lift the same weight because you need a movable pulley.

The mechanical advantage of a pulley system can be maximized by adding more pulleys or rope lengths. For example, if you have a single pulley system, the mechanical advantage is one of the smallest. By using two or three pulleys, up to five times the mechanical advantage can be achieved. You can also gain up to ten times the mechanical advantage by using multiple pulley systems.

The use of a single movable pulley system also adds to the mechanical advantage of the pulley system. In this case, you don’t have to change the direction of the force to lift the weight. In contrast, a movable pulley system requires you to move the rope farther to generate the same force. Using a compound pulley system allows you to lift heavy loads with ease.

Safety Issues When Using Pulley Systems

Pulleys have an incredibly unique structure, consisting of a disc with a groove in the middle and a shaft running through it. A rope or cord is attached to one end of a pulley that turns when force is applied. The other end of the rope is attached to the load. This mechanical advantage means that it is much easier to pull an object using the pulley system than to lift the same object by hand.

Although pulley systems are a common part of many manufacturing processes, some employers do not train their workers to use them properly or install protection to prevent injury. It is important to wear proper PPE and follow standard laboratory safety practices during pulley system activities. Make sure any support structures are strong enough to handle the weight and weight of the rope or rope. If you do fall, be sure to contact your employer immediately.