Product Description

Our Services

Product Design Material Selection

Mold Design Mold Making

Bulk Production Logo Printing

Surface Treatment Assembling

Packaging Door to Door Delivery

| Material | Nylon ,mc nylon, POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc. |

| Color | Black, white, red, green, transparent or any color according to Pantone code |

| Size | As per customer’s requirements |

| Technology | Injection molding, CNC machining, Extrusion |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

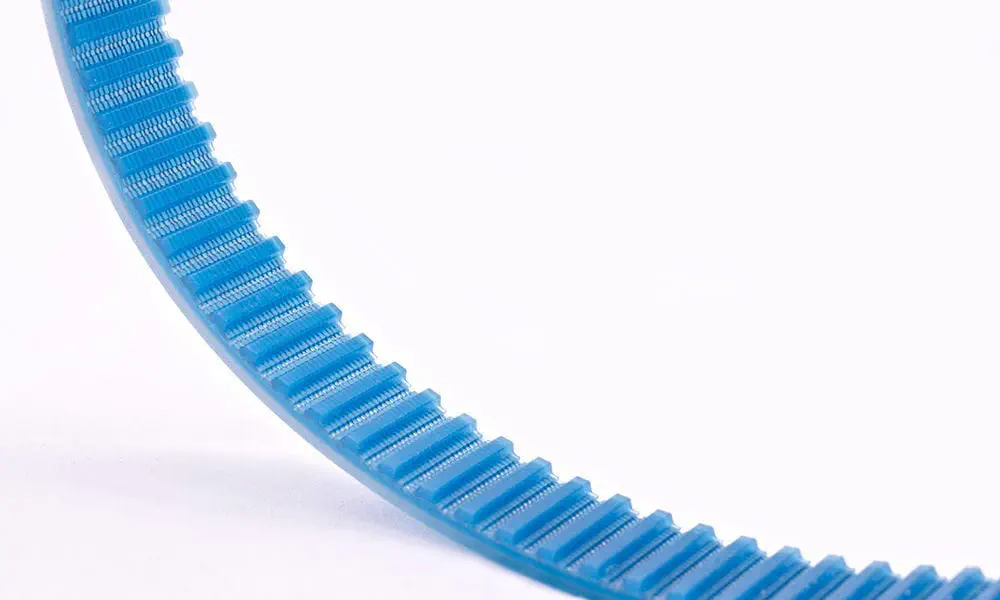

Detail Image

Why Choose Us

Our Machine

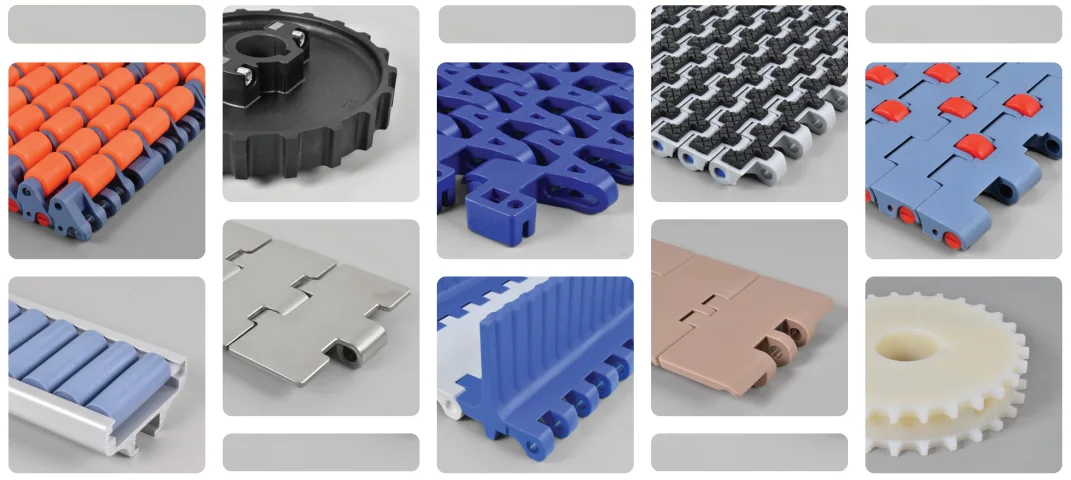

Product Range

Contact Us /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Customized: | Customized |

|---|---|

| Color: | Customized |

| Type: | Rotating Wheel |

| Surface Treatment: | Customized |

| Size: | Customized |

| Material: | Plastic |

| Customization: |

Available

| Customized Request |

|---|

What are the challenges associated with using plastic belts, and how can they be mitigated?

Using plastic belts in various applications comes with its own set of challenges. However, these challenges can be mitigated through various measures. Here’s a detailed explanation:

- 1. Temperature Limitations:

One of the challenges associated with plastic belts is their temperature limitations. Some plastic materials may have lower heat resistance compared to other belt materials like steel or rubber. In high-temperature environments, plastic belts may experience softening, deformation, or even melting, leading to a decrease in their performance and lifespan. To mitigate this challenge, it is important to select plastic belts with materials specifically designed to withstand the temperature range of the application. Additionally, incorporating cooling systems, such as ventilation or water cooling, can help maintain the belt’s temperature within acceptable limits.

- 2. Load Capacity:

Another challenge is the load capacity of plastic belts, particularly in heavy-duty applications. While plastic belts have been engineered to handle significant loads, there may be limitations compared to materials like steel or fabric-reinforced rubber belts. To mitigate this challenge, it is essential to carefully analyze the weight and characteristics of the conveyed materials and select plastic belts with appropriate load-carrying capacity. Reinforcement technologies, such as embedded fibers or metal cords, can be used to enhance the strength and load capacity of plastic belts for heavier applications.

- 3. Abrasion and Wear:

Plastic belts may face challenges related to abrasion and wear, especially in applications where materials with sharp edges or abrasive properties are being conveyed. Continuous contact with abrasive materials can cause premature wear and reduce the belt’s lifespan. To mitigate this challenge, plastic belts with enhanced wear resistance properties, such as specialized surface coatings or harder material formulations, can be used. Regular inspection and maintenance of the belts, including cleaning and proper tensioning, can also help identify and address any signs of wear before they become significant issues.

- 4. Chemical Compatibility:

In applications where plastic belts come into contact with chemicals or substances, compatibility with those chemicals can be a challenge. Certain chemicals may cause degradation or weakening of the belt material, leading to reduced performance or even failure. To mitigate this challenge, it is crucial to select plastic belts with materials that are chemically resistant to the specific substances encountered in the application. Conducting chemical compatibility tests and consulting with belt manufacturers can help ensure that the selected plastic belts can withstand the chemical environment they will be exposed to.

- 5. Belt Tracking and Alignment:

Plastic belts may face challenges related to tracking and alignment on the conveyor system. Misalignment can lead to increased friction, uneven wear, and potential damage to the belt and other conveyor components. To mitigate this challenge, proper belt tracking systems should be implemented, including precision tracking rollers, training idlers, or automated belt tracking mechanisms. Regular maintenance and inspection of the conveyor system can help identify and correct any issues with belt tracking and alignment before they cause significant problems.

- 6. Static Electricity:

Plastic belts can generate static electricity due to friction between the belt and the conveyed materials or the conveyor system. This static electricity can cause issues such as dust attraction, product sticking, or even electrical discharge hazards. To mitigate this challenge, anti-static additives or coatings can be incorporated into the belt material to dissipate static charges. Proper grounding of the conveyor system and the use of static eliminators, such as ionizers or grounding brushes, can also help minimize static electricity-related problems.

In summary, while there are challenges associated with using plastic belts, they can be effectively mitigated through appropriate measures. By carefully selecting belts with suitable temperature resistance, load capacity, and wear resistance, and implementing measures to address issues related to chemical compatibility, belt tracking, and static electricity, the challenges can be managed. Regular maintenance, inspection, and adherence to manufacturer guidelines are essential for ensuring the optimal performance and longevity of plastic belts in various applications.

What role do plastic belts play in ensuring hygiene and cleanliness in food processing applications?

Plastic belts play a crucial role in ensuring hygiene and cleanliness in food processing applications. Here’s a detailed explanation:

- 1. Smooth, Non-Porous Surfaces:

Plastic belts used in food processing applications are designed with smooth, non-porous surfaces. These surfaces prevent the accumulation of food particles, liquids, or other contaminants, reducing the risk of bacterial growth and cross-contamination. Smooth surfaces also make it easier to clean the belts effectively, ensuring optimal hygiene standards are maintained.

- 2. Resistance to Moisture and Chemicals:

Plastic belts for food processing applications are resistant to moisture and a wide range of chemicals used in cleaning and sanitization processes. They can withstand frequent washdowns with water, detergents, and disinfectants without degrading or compromising their structural integrity. This resistance to moisture and chemicals contributes to the overall cleanliness and hygiene of the food processing environment.

- 3. Bacterial Growth Prevention:

Plastic belts inhibit bacterial growth due to their non-porous surfaces and resistance to moisture. Unlike fabric belts, which can absorb and retain moisture, plastic belts do not provide a favorable environment for bacteria to thrive. By minimizing bacterial growth, plastic belts help maintain the cleanliness and safety of food products during processing.

- 4. Compatibility with Sanitization Processes:

Plastic belts used in food processing applications are designed to withstand regular sanitization procedures. They can be easily cleaned using standard cleaning agents, high-pressure washdowns, or even steam cleaning. Plastic belts are resilient to the harsh chemicals and high temperatures often employed in food processing facilities for effective sanitization, ensuring that the belts themselves remain hygienic and do not become a source of contamination.

- 5. Compliance with Food Safety Standards:

Plastic belts used in the food processing industry are often manufactured from food-grade materials that comply with relevant safety regulations. These materials are chosen for their ability to meet strict food safety requirements, including FDA (Food and Drug Administration) or EU (European Union) regulations. By using plastic belts that meet these standards, food processors can ensure that their operations align with the necessary hygiene and safety guidelines.

- 6. Easy Maintenance and Inspection:

Plastic belts are relatively easy to maintain and inspect for cleanliness. Their smooth surfaces allow for quick visual inspection to detect any visible contamination or debris. If cleaning is required, plastic belts can be easily cleaned using appropriate methods, reducing downtime and allowing for efficient production processes.

In summary, plastic belts play a vital role in ensuring hygiene and cleanliness in food processing applications. Their smooth, non-porous surfaces, resistance to moisture and chemicals, prevention of bacterial growth, compatibility with sanitization processes, compliance with food safety standards, and ease of maintenance contribute to maintaining a clean and safe environment for food processing operations.

Can you explain the advantages of using plastic belts over traditional materials in conveyor systems?

Using plastic belts in conveyor systems offers several advantages over traditional materials such as rubber or fabric. Plastic belts, also known as polymer belts or synthetic belts, are made from various types of plastic materials and provide unique characteristics that make them desirable for conveyor applications. Here’s a detailed explanation of the advantages of using plastic belts over traditional materials in conveyor systems:

- Durability and Longevity:

- Versatility and Customization:

- Hygienic and Easy to Clean:

- Low Friction and Energy Efficiency:

- Chemical Resistance:

- Lightweight and Easy Installation:

Plastic belts are known for their durability and longevity. They are resistant to wear, abrasion, and impact, allowing them to withstand harsh operating conditions. Unlike rubber or fabric belts, plastic belts do not easily degrade or stretch over time. They can handle heavy loads and maintain their shape and performance for extended periods, resulting in reduced maintenance and replacement costs for conveyor systems.

Plastic belts offer versatility and customization options for conveyor systems. They can be manufactured in various sizes, widths, and configurations to meet specific application requirements. Plastic belts can have different surface patterns, such as smooth, textured, or perforated, providing enhanced grip, airflow, or product release capabilities. Additionally, plastic belts can be designed with specialized features like high temperature resistance, chemical resistance, or anti-static properties, making them suitable for diverse industries and conveyor applications.

Plastic belts are highly hygienic and easy to clean, making them ideal for industries with strict cleanliness and sanitation standards. Unlike fabric belts, plastic belts do not absorb liquids or harbor bacteria, reducing the risk of contamination in food processing, pharmaceutical, or other clean environments. Plastic belts can be easily cleaned using water, steam, or cleaning agents, ensuring optimal hygiene and compliance with industry regulations.

Plastic belts offer low friction characteristics, resulting in energy-efficient conveyor systems. The reduced friction between the belt and the conveyor components minimizes power consumption, allowing for cost savings and environmental benefits. Additionally, the low friction properties of plastic belts contribute to smoother and quieter operation, reducing noise levels in the workplace.

Plastic belts exhibit excellent chemical resistance, making them suitable for conveyor systems that handle corrosive or aggressive substances. They can withstand exposure to various chemicals, oils, solvents, and cleaning agents without deteriorating or experiencing significant damage. Plastic belts’ chemical resistance ensures their longevity and reliability in industries such as chemical processing, pharmaceuticals, or wastewater treatment.

Plastic belts are lightweight compared to traditional materials, facilitating easy installation and maintenance of conveyor systems. The reduced weight of plastic belts reduces the strain on conveyor components, extending their lifespan. Additionally, the lightweight nature of plastic belts simplifies handling during installation or replacement, improving efficiency and reducing downtime.

In summary, using plastic belts in conveyor systems offers significant advantages over traditional materials. They provide durability, versatility, and customization options, ensuring long-lasting and efficient performance. Plastic belts are hygienic, easy to clean, and resistant to chemicals, making them suitable for industries with strict cleanliness requirements. They offer low friction and energy efficiency, contributing to cost savings and environmental benefits. Moreover, plastic belts are lightweight and easy to install, simplifying maintenance and reducing downtime. These advantages make plastic belts a preferred choice in various industries for their conveyor system needs.

editor by CX 2024-02-26