Product Description

Auto Part car Nylon/Metal/Plastic Rivet/Nuts/Bolts/Screws/Clips/Retainer/Fasteners

We have more than 3000 kinds auto clips.

Different typies ,colors and packing can be customized.

We have stock, ready-made molds, can be shipped quickly.

If you have interested in our priducts,we can offer free sample.

Product Description

Features:

- Be made of Environmental friendly plastic which is high quality and durable for using.

- This bumper rivets fasteners set are made of plastic,won’t rust or rot. can use for a long time.

- It is very easy to use, it is push type, rivet heads pressure expand to its legs, easy to install quickly.

- They are be used for trim panel clips, door trim clips, door panel clips, bumper clips, Fender clips,

- engine cover and splash shield retainers replacement.

- These clips are suitable for firmly holding anything within a fit diameter hole.

| Product name | Nylon Plastic Push Snap Rivets/Clips/Fasters |

| Colour | Customized |

| Material | POM,PP,Plastic,Nylon |

| Birthplace | Chinese Mainland |

| Warranty | 1 year |

| Port | HangZhou,ZheJiang ,HangZhou,HangZhou |

| MOQ | 1000 |

| Payment | TT, Western Union, Ali-pay, Credit Card, Bank transfer, Cash |

| Packing | packaging can according to the customers’ requirements can packed in plastic bags or in the plastic boxes |

More Types wait your inquiry !

Let’s talk more !

Installation Process

Packaging

Company Profile

1.CZPT is 1 of the leading exporter in China, specializing in the field of auto parts since 2002.

2.We are a professional factory located in China with the most efficient exporting process.

We can supply Nylon/Metal/Plastic/Rivet/Nuts/Bolts/Screws/Clips/Retainer/Fasteners

3.We have strong relationships with our clients in most of around the world, North America, Europe, South America, South Asia, Middle East and Africa!

4.The products we provide can match with your different requirements.

Choose us, CZPT never let you down ! !

Our Services & Strength

1. More than 3000 typies of auto clips, 20 sets of different tool kit and 3D accessories strip

2. All of our products are in high quality.

3. 100% test before delivery , 100% responssible for quality issue aftersale.

4. MOQ 1000 pcs, accept small order.

We don’t just sell goods, we sell partnership. We provide customers with good service, get the trust of customers with a good reputation.

No matter your order is large or small, we are CZPT to provide you with the utmost services and 100% responsible for quality aftersale.

Wholeheartedly to offer each of our customers the best products, looking forward to servicing your needs.

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

We’ll show you the photos of the products and packages before you pay the balance.

Western Union/Credit Card

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 7-10 days.

The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock.

But the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Auto Fastener & Clip |

|---|---|

| Products Name: | Auto Fastener Clip Auto Accessories |

| Application: | All Car |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

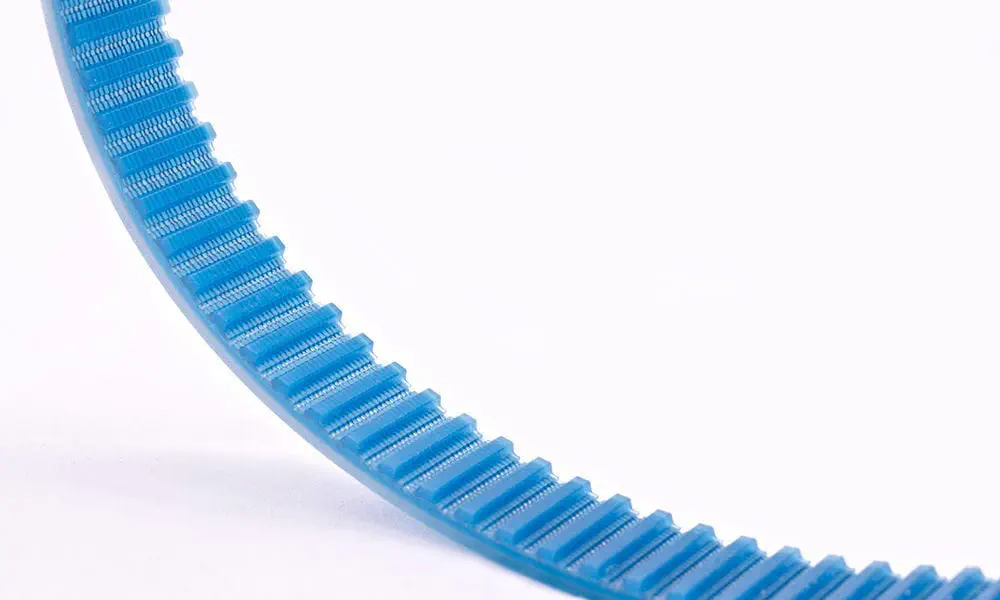

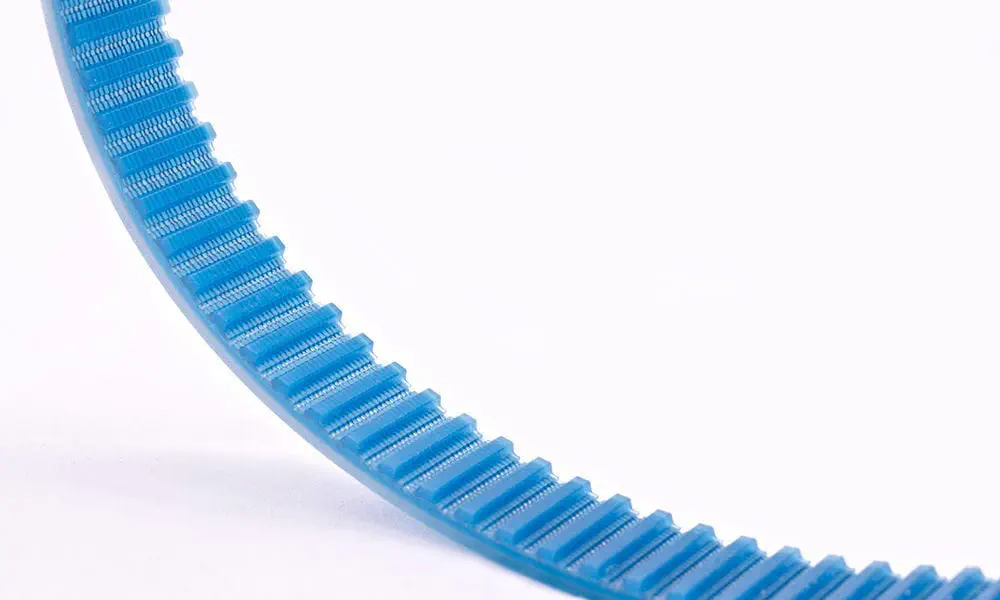

What innovations and advancements have been made in plastic belt technology in recent years?

In recent years, there have been several notable innovations and advancements in plastic belt technology. Here’s a detailed explanation:

- 1. Enhanced Material Formulations:

One significant advancement in plastic belt technology is the development of enhanced material formulations. Manufacturers have been working on creating new polymer blends or modifying existing ones to improve the performance characteristics of plastic belts. These advancements focus on enhancing properties such as strength, flexibility, wear resistance, temperature resistance, and chemical resistance. The result is the availability of plastic belts that can withstand more demanding applications, exhibit greater durability, and offer improved overall performance.

- 2. Reinforcement Technologies:

Reinforcement technologies have been introduced to enhance the strength and load-carrying capacity of plastic belts. Reinforcements such as embedded fibers, fabric layers, or metal cords are incorporated into the belt structure to provide increased tensile strength and dimensional stability. These advancements allow plastic belts to handle heavier loads, endure higher tension levels, and resist elongation or stretching during operation. Reinforced plastic belts are particularly beneficial in industries such as logistics, manufacturing, or mining where heavy-duty conveying is required.

- 3. Modular Belt Designs:

Modular plastic belt designs have gained popularity due to their versatility and ease of maintenance. These belts consist of interlocking modules or links that can be easily assembled and disassembled, allowing for quick belt repairs, replacements, or modifications. The modular design also enables customization of belt width, length, and configuration to suit specific conveyor systems and applications. Additionally, modular plastic belts offer improved hygiene as they have fewer crevices and joints where debris or contaminants can accumulate, making them ideal for industries such as food processing or pharmaceuticals.

- 4. Advanced Surface Coatings:

Advancements in surface coatings have contributed to the performance and functionality of plastic belts. Innovative coatings are applied to the belt surface to enhance properties such as slip resistance, release characteristics, abrasion resistance, or chemical resistance. These coatings can improve the belt’s traction, prevent product sticking or slipping, prolong belt life, and protect against chemical damage. Additionally, specialized coatings with antimicrobial properties have been developed to inhibit the growth of bacteria or microorganisms on the belt surface, making them suitable for applications with strict hygiene requirements.

- 5. Conveyor System Integration:

Recent advancements in plastic belt technology have also focused on improving integration with conveyor systems. Manufacturers have developed innovative designs for sprockets, guides, and other components that ensure efficient belt tracking, reduced friction, and improved overall system performance. These advancements help minimize belt wear, reduce energy consumption, and enhance the lifespan of plastic belts and other conveyor system components.

- 6. Sustainability and Recycling:

There is an increasing emphasis on sustainability in plastic belt technology. Manufacturers are exploring eco-friendly materials and production processes to reduce the environmental impact of plastic belts. Some advancements include the use of recycled or biodegradable materials in belt manufacturing, as well as the development of recycling programs to collect and process used plastic belts at the end of their lifespan. These initiatives aim to minimize waste generation, conserve resources, and promote the circular economy in the conveyor industry.

In summary, recent years have seen significant innovations and advancements in plastic belt technology. Enhanced material formulations, reinforcement technologies, modular belt designs, advanced surface coatings, improved conveyor system integration, and a focus on sustainability have all contributed to the development of more robust, versatile, and environmentally friendly plastic belts. These advancements offer improved performance, durability, customization options, and ease of maintenance, making plastic belts a reliable choice for a wide range of conveyor applications.

How do environmental factors affect the performance of plastic belts in outdoor applications?

Environmental factors can significantly impact the performance of plastic belts in outdoor applications. Here’s a detailed explanation:

- 1. Temperature:

The temperature in outdoor environments can vary widely, and extreme temperatures can affect the performance of plastic belts. High temperatures can cause plastic belts to soften, deform, or lose their structural integrity. On the other hand, low temperatures can make plastic belts brittle and more prone to cracking or breakage. It’s important to choose plastic belts that are specifically designed to withstand the temperature range of the outdoor application to ensure optimal performance and longevity.

- 2. UV Exposure:

Plastic belts exposed to direct sunlight in outdoor applications are susceptible to UV degradation. Prolonged exposure to UV radiation can cause the material to become brittle, fade in color, and weaken over time. UV-resistant plastic belts, typically made with additives or coatings that provide UV protection, are available to mitigate the effects of UV exposure. Using UV-resistant belts is crucial to maintain the performance and lifespan of plastic belts in outdoor environments.

- 3. Moisture and Humidity:

Outdoor environments often involve exposure to moisture and humidity, which can impact the performance of plastic belts. Excessive moisture can cause plastic belts to absorb water, leading to dimensional changes, reduced strength, and increased risk of mold or bacterial growth. High humidity can also affect the friction characteristics of the belts, potentially impacting their grip or slip resistance. Using moisture-resistant or waterproof plastic belts and implementing proper drainage and ventilation systems can help mitigate the effects of moisture and humidity.

- 4. Dust and Debris:

Outdoor applications are prone to the accumulation of dust, dirt, and debris. These particles can enter the conveyor system and become trapped between the plastic belt and other components, leading to increased friction, wear, and potential belt damage. Regular cleaning and maintenance practices, such as periodic belt cleaning or installing effective dust control measures, are essential to prevent the buildup of dust and debris and ensure the smooth operation of plastic belts in outdoor environments.

- 5. Mechanical Stress:

Outdoor applications may involve exposure to mechanical stressors such as heavy loads, impacts, or abrasive materials. Plastic belts should be selected based on their mechanical properties to withstand the specific demands of the outdoor environment. Reinforced or heavy-duty plastic belts with enhanced tensile strength and impact resistance may be necessary to ensure reliable performance and prevent premature failure.

- 6. Corrosive Substances:

In certain outdoor applications, plastic belts may come into contact with corrosive substances, such as chemicals or saltwater. Corrosive substances can degrade the plastic material, leading to reduced belt strength and potential failure. It’s important to choose plastic belts that are chemically resistant to the specific substances present in the outdoor environment to ensure long-term performance and minimize the risk of belt damage.

In summary, environmental factors such as temperature variations, UV exposure, moisture and humidity, dust and debris, mechanical stress, and corrosive substances can all impact the performance of plastic belts in outdoor applications. Selecting plastic belts specifically designed to withstand these environmental challenges, implementing proper maintenance practices, and considering additional protective measures can help ensure the longevity and reliable operation of plastic belts in outdoor settings.

Are there specific applications where plastic belts outperform other types of conveyor belts?

Yes, there are specific applications where plastic belts outperform other types of conveyor belts. Here’s a detailed explanation:

- 1. Hygienic Environments:

Plastic belts are particularly well-suited for applications in hygienic environments such as the food and beverage industry, pharmaceuticals, and healthcare. They offer smooth, non-porous surfaces that are easy to clean and sanitize, reducing the risk of bacterial growth and cross-contamination. Plastic belts’ resistance to chemicals and moisture makes them suitable for industries that require regular washdowns and adherence to strict hygiene standards. In these applications, plastic belts outperform other types of belts, such as fabric or metal belts, which may be more difficult to clean or prone to bacterial buildup.

- 2. Product Accumulation and Diverting:

Plastic belts, especially modular plastic belts, excel in applications that require product accumulation and diverting. The interlocking modules on modular plastic belts allow for smooth product flow and accumulation without the need for additional components or complex control systems. These belts can also divert products to different lanes or conveyors using simple mechanisms. Plastic belts’ flexibility and adaptability make them an excellent choice for applications where precise product control and diversion are necessary, such as sorting systems in distribution centers or assembly lines with multiple workstations.

- 3. Gentle Product Handling:

Plastic belts, particularly those with cleats or vacuum features, are preferred when gentle product handling is required. The cleats on plastic belts help prevent product slippage and ensure stable conveying, making them suitable for incline or decline applications or conveying delicate items. Vacuum plastic belts utilize suction to hold lightweight or fragile products securely during transport, minimizing product damage. These belts outperform other types of belts, such as roller or chain conveyors, which may cause friction, impact, or abrasion on the conveyed products.

- 4. Noise Reduction:

Plastic belts offer noise reduction advantages over other types of conveyor belts. The damping properties of plastic materials help absorb vibrations and reduce noise generated during operation. This makes plastic belts a preferred choice in applications where noise levels need to be minimized, such as retail environments, offices, or manufacturing facilities with strict noise regulations. Other types of belts, such as metal belts or fabric belts, may produce higher levels of noise due to their material properties or mechanical design.

- 5. Corrosive or Wet Environments:

Plastic belts are highly resistant to chemicals, oils, and moisture, making them suitable for applications in corrosive or wet environments. In industries such as chemical processing, wastewater treatment, or mining, where exposure to corrosive substances or water is common, plastic belts offer superior performance and durability compared to belts made of materials like metal or fabric. Plastic belts’ resistance to corrosion and moisture-related damage ensures reliable operation and extends the service life of the conveyor system.

In summary, plastic belts outperform other types of conveyor belts in specific applications where hygiene, product accumulation and diverting, gentle handling, noise reduction, and resistance to corrosive or wet environments are critical. Understanding the unique advantages of plastic belts in these applications helps industries make informed decisions when selecting the most suitable conveyor belt for their material handling needs.

editor by CX 2024-01-12