Product Description

Our Services

Product Design Material Selection

Mold Design Mold Making

Bulk Production Logo Printing

Surface Treatment Assembling

Packaging Door to Door Delivery

| Material | Nylon ,mc nylon, POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc. |

| Color | Black, white, red, green, transparent or any color according to Pantone code |

| Size | As per customer’s requirements |

| Technology | Injection molding, CNC machining, Extrusion |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

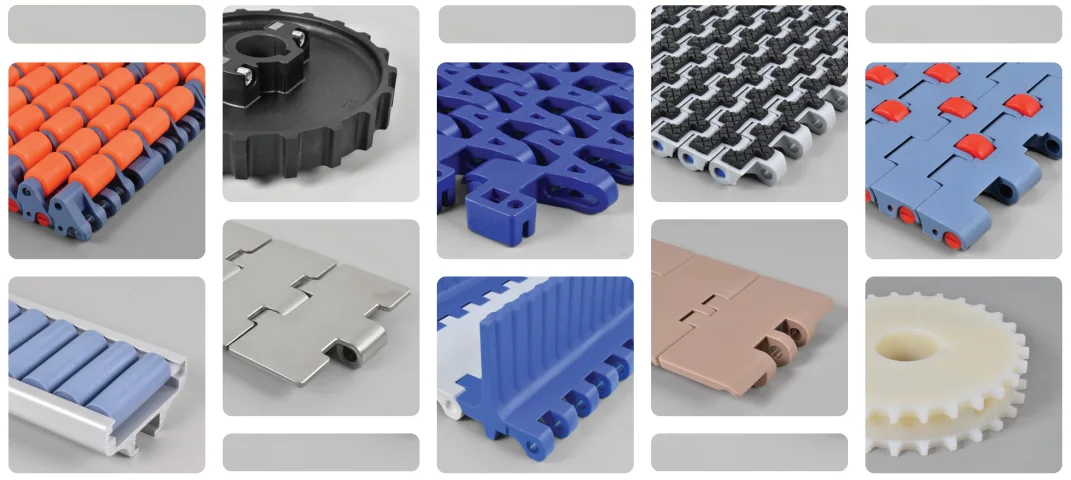

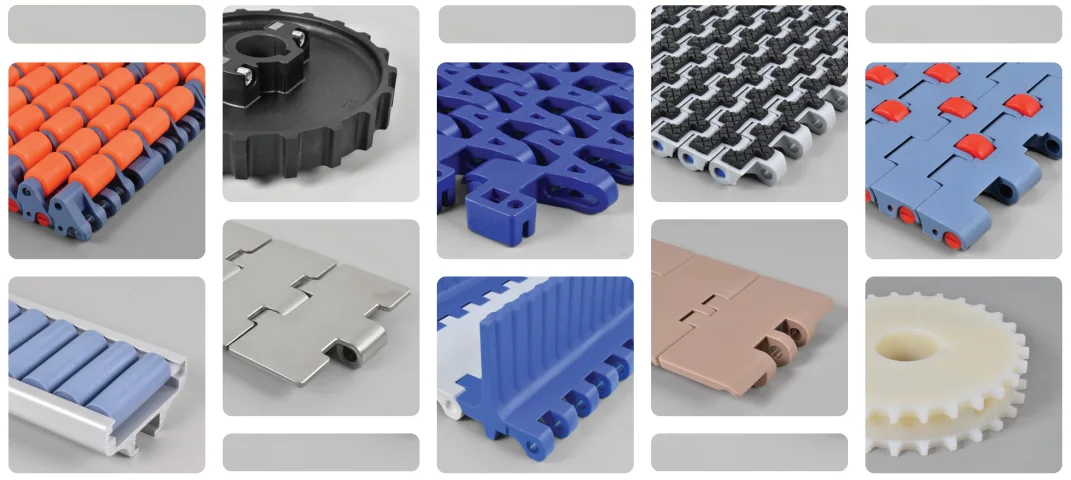

Detail Image

Our Factory

CZPT is a leading manufacture of OEM parts in rubber & plastic & metal parts. We are always pursuing providing better quality products in shorter period. With a knowledgeable team which has experience in molding and production, we are confident to help you develop and manufacture your product

Customization Capabilities

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Pulley Sizes: | Type D |

|---|---|

| Manufacturing Process: | Forging |

| Material: | Plastic |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | Order Sample For sample price, package information, and logisti

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can plastic belts be used in heavy-duty applications, such as mining or construction?

Yes, plastic belts can indeed be used in heavy-duty applications, including mining and construction. Here’s a detailed explanation:

- Plastic Belt Advancements:

In recent years, there have been significant advancements in plastic belt technology, leading to the development of robust and high-performance plastic belts. These advancements include enhanced material formulations, reinforcement technologies, and improved belt designs, which have expanded the capabilities of plastic belts and made them suitable for heavy-duty applications.

- Strength and Load-Carrying Capacity:

Plastic belts designed for heavy-duty applications are engineered to have excellent strength and load-carrying capacity. Reinforcement technologies, such as embedded fibers, fabric layers, or metal cords, are incorporated into the belt structure to enhance tensile strength and dimensional stability. These reinforcements enable plastic belts to handle heavy loads, endure high tension levels, and resist elongation or stretching during operation. As a result, plastic belts can effectively convey bulk materials, aggregates, or heavy equipment in mining and construction environments.

- Wear and Impact Resistance:

Plastic belts used in heavy-duty applications are designed to exhibit superior wear and impact resistance. They are engineered to withstand the abrasive nature of mining operations or the harsh conditions encountered in construction sites. Advanced material formulations and surface coatings are employed to enhance the belt’s durability, preventing premature wear and tear caused by abrasive materials or impacts from heavy loads. This ensures that plastic belts can maintain their performance and reliability even in demanding operating conditions.

- Chemical and Moisture Resistance:

Plastic belts for heavy-duty applications in mining or construction often have excellent chemical and moisture resistance properties. They are designed to withstand exposure to various chemicals, oils, solvents, or moisture commonly found in these environments. This resistance prevents chemical degradation, swelling, or weakening of the belt material, ensuring its long-term performance and reliability. Additionally, plastic belts with moisture-resistant properties are less prone to damage from water or humidity, making them suitable for outdoor applications or environments with high moisture levels.

- Customization and Modular Designs:

Plastic belts offer customization options and modular designs that make them adaptable to the specific requirements of heavy-duty applications. Manufacturers provide a range of belt widths, lengths, and configurations to accommodate different conveyor systems and operational needs. The modular design of plastic belts allows for easy installation, repair, or replacement, minimizing downtime and ensuring continuous operation in mining or construction sites where efficiency is crucial.

- Benefits of Plastic Belts:

Using plastic belts in heavy-duty applications offers several advantages. Plastic belts are generally lightweight, which reduces the load on conveyor systems, lowers energy consumption, and simplifies installation and maintenance. They also have a lower coefficient of friction compared to other belt materials, resulting in reduced power requirements and improved conveyor efficiency. Additionally, plastic belts are resistant to rust, corrosion, and rot, making them suitable for outdoor or wet environments commonly encountered in mining and construction.

In summary, plastic belts can be successfully used in heavy-duty applications such as mining or construction. With advancements in material formulations, reinforcement technologies, and belt designs, plastic belts now offer the required strength, load-carrying capacity, wear resistance, and chemical resistance to withstand the demanding conditions of these industries. The customization options, modular designs, and additional benefits of plastic belts make them a reliable choice for efficient and durable conveying in heavy-duty applications.

How does the durability of plastic belts compare to other materials in conveyor systems?

When comparing the durability of plastic belts to other materials used in conveyor systems, several factors come into play. Here’s a detailed explanation:

- 1. Wear Resistance:

Plastic belts generally offer good wear resistance, allowing them to withstand the demands of many industrial applications. The specific wear resistance can vary depending on the type of plastic material used for the belt. Some plastic materials, such as polyurethane (PU) or acetal (POM), exhibit excellent wear resistance and can withstand abrasive environments better than other materials like fabric or rubber belts. However, in high-intensity applications with heavy loads or sharp objects, metal belts may provide superior wear resistance compared to plastic belts.

- 2. Impact Resistance:

Plastic belts typically have good impact resistance, especially when compared to rigid materials like metal belts. Plastic belts can absorb and dissipate impact forces, reducing the risk of damage or breakage. This makes plastic belts suitable for applications where the conveyed products may encounter impacts during loading, unloading, or handling processes. However, in extremely demanding applications with heavy or sharp impacts, specialized metal belts or reinforced fabric belts may offer higher impact resistance than plastic belts.

- 3. Chemical Resistance:

Plastic belts generally exhibit excellent chemical resistance compared to other materials like fabric or rubber belts. They can withstand exposure to a wide range of chemicals, oils, solvents, and cleaning agents without significant degradation. This makes plastic belts suitable for industries where corrosive substances or chemical cleaning agents are present. In contrast, fabric or rubber belts may deteriorate or experience chemical damage when exposed to aggressive substances.

- 4. Moisture Resistance:

Plastic belts are highly resistant to moisture, making them suitable for applications in wet environments or where frequent washdowns are required. Unlike fabric belts that can absorb moisture and become weakened, plastic belts maintain their structural integrity and performance even when exposed to water or high humidity. Metal belts, on the other hand, may be prone to corrosion when exposed to moisture, requiring additional protective measures.

- 5. Temperature Resistance:

The temperature resistance of plastic belts can vary depending on the specific plastic material used. Some plastic materials, such as polypropylene (PP) or polyethylene (PE), have lower temperature resistance compared to other materials like metal belts. However, there are plastic belt options available, such as polyurethane (PU) or polyvinyl chloride (PVC), that offer high-temperature resistance and can withstand elevated temperatures in industrial applications. It’s essential to select a plastic belt that matches the temperature range of the intended application.

- 6. Longevity and Maintenance:

The longevity and maintenance requirements of plastic belts can be favorable compared to other materials. Plastic belts typically have a longer lifespan than fabric belts, as they are less prone to fraying, tearing, or stretching. They also require minimal maintenance, as they do not need regular lubrication or tension adjustments like metal belts. Plastic belts can be easily cleaned and sanitized, prolonging their service life. However, metal belts may offer exceptional longevity and require minimal maintenance as well.

In summary, plastic belts offer good durability in many industrial applications, particularly when it comes to wear resistance, impact resistance, chemical resistance, moisture resistance, and ease of maintenance. However, in certain demanding applications with heavy loads, sharp impacts, or extreme temperatures, specialized metal belts or reinforced fabric belts may provide superior durability. It’s crucial to assess the specific requirements of the application and select the most appropriate belt material based on the expected operating conditions and the desired level of durability.

How do plastic belts contribute to the efficiency and functionality of conveyor systems?

Plastic belts play a crucial role in enhancing the efficiency and functionality of conveyor systems. Here’s a detailed explanation:

- 1. Lightweight and High Strength:

Plastic belts are typically lightweight yet offer high strength and load-carrying capacity. Their lightweight nature reduces the overall weight of the conveyor system, resulting in lower energy consumption and reduced strain on the system’s components. Despite their lightness, plastic belts can handle heavy loads, making them suitable for a wide range of applications while maintaining efficiency and functionality.

- 2. Flexibility and Adaptability:

Plastic belts are highly flexible and adaptable, allowing them to conform to the shape of the conveyor system. This flexibility enables the belts to navigate around pulleys, curves, and other obstacles smoothly. It also facilitates easy installation and adjustment of the conveyor system, making it more versatile and accommodating to different layout configurations. The adaptability of plastic belts contributes to efficient material handling and optimized system functionality.

- 3. Low Friction and Energy Efficiency:

Plastic belts have low friction characteristics, which significantly reduce energy consumption in conveyor systems. The low coefficient of friction between the belt and the conveyor components minimizes resistance and allows for smooth movement of materials. This low friction property not only enhances the efficiency of the system but also reduces wear and tear on the belt and other system components, leading to extended service life and reduced maintenance requirements.

- 4. Chemical Resistance and Hygiene:

Plastic belts are often resistant to chemicals, oils, and other substances, making them suitable for conveying materials in various industries, including food processing, pharmaceuticals, and manufacturing. Their chemical resistance ensures that the belts can withstand exposure to corrosive or potentially harmful substances without degradation or contamination. Additionally, plastic belts can be easily cleaned and sanitized, promoting hygiene and meeting strict industry standards in applications where cleanliness is essential.

- 5. Noise Reduction:

Compared to traditional conveyor belts made of materials like metal or rubber, plastic belts offer noise reduction benefits. Plastic belts produce less noise during operation due to their inherent damping properties. This noise reduction is especially advantageous in environments where noise levels need to be minimized, such as in retail settings or sensitive manufacturing processes, contributing to a quieter and more comfortable work environment.

- 6. Durability and Longevity:

Plastic belts are known for their durability and longevity. They are resistant to wear, abrasion, and impact, ensuring reliable and long-lasting performance in demanding conveyor applications. Plastic belts are less susceptible to damage from moisture, temperature variations, and other environmental factors, which can compromise the functionality of other belt materials. Their durability and longevity contribute to increased uptime, reduced downtime, and overall cost savings in conveyor system operation.

In summary, plastic belts offer several advantages that contribute to the efficiency and functionality of conveyor systems. Their lightweight yet high-strength construction, flexibility and adaptability, low friction characteristics, chemical resistance, noise reduction properties, and durability make them valuable components in a wide range of industries. By utilizing plastic belts, conveyor systems can achieve improved material handling efficiency, reduced energy consumption, enhanced hygiene, minimized maintenance requirements, and extended service life.

editor by CX 2024-02-25

China Standard Low Cost Injection Molding Custom V Belt Black Pulley Plastic Timing Belts and Pulleys cv axle puller

Product Description

Our Services

Product Design Material Selection

Mold Design Mold Making

Bulk Production Logo Printing

Surface Treatment Assembling

Packaging Door to Door Delivery

| Material | Nylon ,mc nylon, POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc. |

| Color | Black, white, red, green, transparent or any color according to Pantone code |

| Size | As per customer’s requirements |

| Technology | Injection molding, CNC machining, Extrusion |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

Detail Image

50+ types material of plastic, rubber, PU to help you perfectly adapt to the product application scenarios

Customize product features according to requirements:

1. Achieve medical-grade and food-grade products

2. Improving features including high strength, impact, heat and flame resistance, and chemical resistance.etc through various additives

3. Other appearances can achieve various customized services such as color, texture, hardness, pattern, and logo printing

4. Widely used in various industries: Automotive, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc.

Our products are widely used in various fields:

Why Choose Us

Our Machine

Product Range

Contact Us /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type E |

| Manufacturing Process: | Forging |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | Order Sample For sample price, package information, and logisti

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do plastic belts contribute to reducing friction and energy consumption in conveyor systems?

Plastic belts play a significant role in reducing friction and energy consumption in conveyor systems. Here’s a detailed explanation:

- Low Coefficient of Friction:

Plastic belts are engineered to have a low coefficient of friction, which means they offer minimal resistance to the movement of conveyed materials. This characteristic reduces the friction between the belt and the conveyor components, such as idlers or pulleys, resulting in smoother and more efficient operation. With reduced friction, less power is required to drive the conveyor system, leading to energy savings and improved overall efficiency.

- Lightweight Construction:

Plastic belts are generally lightweight compared to other belt materials, such as rubber or metal. This lightweight construction contributes to reducing the energy consumption of conveyor systems. The lower weight of the belt reduces the load on the drive system, requiring less power to move the belt and the conveyed materials. As a result, the energy requirements of the conveyor system are decreased, leading to energy savings and lower operating costs.

- Reduced Belt-to-Belt Friction:

In conveyor systems where multiple belts are used, plastic belts can help reduce belt-to-belt friction. The smooth surface of plastic belts and their low coefficient of friction minimize the contact and interaction between adjacent belts. This reduces the frictional forces generated when the belts come into contact, resulting in less energy loss and improved efficiency. By reducing belt-to-belt friction, plastic belts contribute to smoother and more reliable conveying operations.

- Improved Belt Flexibility:

Plastic belts are designed to be flexible, allowing them to adapt to the contours of conveyor systems more effectively. The flexibility of plastic belts helps to maintain proper belt alignment and reduces the occurrence of misalignment-related friction. When a belt is misaligned, it can cause increased friction and wear on the belt and the conveyor components, leading to higher energy consumption. By promoting better belt alignment, plastic belts minimize frictional losses and contribute to energy efficiency.

- Efficient Transfer of Power:

Plastic belts offer efficient power transfer within the conveyor system. The low coefficient of friction and lightweight construction of plastic belts allow for more effective transmission of power from the drive system to the belt. This efficient transfer of power ensures that a greater portion of the energy input is utilized for moving the conveyed materials, rather than being lost as heat or wasted due to friction. As a result, the overall energy consumption of the conveyor system is reduced.

In summary, plastic belts contribute to reducing friction and energy consumption in conveyor systems through their low coefficient of friction, lightweight construction, reduced belt-to-belt friction, improved belt flexibility, and efficient transfer of power. These characteristics not only enhance the overall efficiency of the conveyor system but also result in energy savings and reduced operating costs. By choosing plastic belts, industries can optimize their conveyor operations, minimize energy usage, and achieve more sustainable and cost-effective material handling processes.

What factors should be considered when selecting plastic belts for different industrial applications?

When selecting plastic belts for different industrial applications, several factors should be taken into consideration. Here are the key factors to consider:

- 1. Application Requirements:

Understand the specific requirements of the application. Consider factors such as the type of products being conveyed, the weight and size of the loads, the desired conveying speed, the operating temperature range, the presence of moisture or chemicals, and any special handling needs. Clear knowledge of the application requirements will help in selecting a plastic belt with the appropriate characteristics and capabilities.

- 2. Belt Configuration and Design:

Consider the belt configuration and design that best suits the application. Different plastic belts come in various configurations, including flat-top, flush-grid, raised-rib, and modular designs. Evaluate the belt’s surface texture, open area percentage, and any specialized features such as cleats, perforations, or vacuum capabilities. The belt design should align with the product characteristics, conveying conditions, and any specific requirements like incline/decline conveying or product diverting.

- 3. Material Selection:

Choose the appropriate plastic material for the belt based on the application’s demands. Common plastic materials used for belts include polyethylene (PE), polypropylene (PP), acetal (POM), polyvinyl chloride (PVC), and polyurethane (PU). Consider factors such as chemical resistance, temperature resistance, wear resistance, flexibility, and food-grade compliance. Ensure the selected material can withstand the operating conditions and environmental factors that the belt will encounter.

- 4. Load Capacity and Durability:

Evaluate the load capacity requirements of the application and select a plastic belt that can handle the intended loads. Consider the weight capacity per unit width and the overall strength and durability of the belt. Factors such as the belt’s tensile strength, impact resistance, and resistance to abrasion or wear are important for ensuring the longevity and reliability of the belt in demanding industrial environments.

- 5. Cleanability and Hygiene:

In industries with stringent hygiene requirements, such as food processing or pharmaceuticals, prioritize plastic belts that are easy to clean and sanitize. Look for belts with smooth, non-porous surfaces that resist bacterial growth and are compatible with regular washdown procedures. Consider whether the belt can withstand cleaning agents and temperature variations without degradation or compromising its hygienic properties.

- 6. Compatibility with Conveyor System:

Ensure the selected plastic belt is compatible with the existing or planned conveyor system. Consider factors such as the belt’s width and length options, the type of conveyor system (e.g., flatbed, roller, or modular), the compatibility of the belt’s sprockets or pulleys with the conveyor system, and the ease of installation and maintenance. Proper compatibility will ensure smooth integration and optimal performance of the belt within the conveyor system.

- 7. Cost and Long-Term Value:

Evaluate the cost-effectiveness and long-term value of the plastic belt. Consider not only the upfront cost of the belt but also its expected lifespan, maintenance requirements, and potential savings in terms of reduced downtime, increased productivity, and lower operational costs. Balancing cost considerations with the desired performance and durability will help in selecting a plastic belt that delivers the best value for the specific industrial application.

By considering these factors in the selection process, industries can choose the most suitable plastic belt that meets the unique requirements of their industrial applications, ensuring efficient and reliable material handling operations.

In what industries are plastic belts commonly employed for material handling?

Plastic belts are widely employed for material handling in various industries. Here’s a detailed explanation:

- 1. Food and Beverage Industry:

In the food and beverage industry, plastic belts are extensively used for material handling due to their hygienic properties, chemical resistance, and ease of cleaning. They are employed in applications such as conveying fruits, vegetables, baked goods, packaged foods, beverages, and dairy products. Plastic belts ensure safe and efficient transportation of food items while adhering to strict hygiene standards and preventing contamination.

- 2. Packaging and Logistics Industry:

Plastic belts find wide application in the packaging and logistics industry for the movement of packages, parcels, and containers. They are used in conveyor systems for sorting, merging, diverting, and accumulating packages during packaging, warehousing, and distribution processes. Plastic belts offer high strength, flexibility, and durability, allowing efficient handling of various package sizes and shapes.

- 3. Manufacturing and Assembly Industry:

In manufacturing and assembly processes, plastic belts are commonly employed for material handling tasks. They facilitate the transportation of components, parts, and products between different stages of production lines. Plastic belts can handle heavy loads, endure high-speed operations, and navigate through complex layouts, making them suitable for applications in automotive, electronics, appliances, and other manufacturing sectors.

- 4. Pharmaceutical and Healthcare Industry:

The pharmaceutical and healthcare industry relies on plastic belts for material handling in various stages of production, including drug manufacturing, packaging, and distribution. Plastic belts offer chemical resistance, easy cleanability, and compliance with industry regulations. They are used for conveying vials, bottles, blister packs, medical devices, and other pharmaceutical products in a controlled and hygienic environment.

- 5. E-commerce and Retail Industry:

Plastic belts play a vital role in the e-commerce and retail industry for material handling in distribution centers, fulfillment centers, and retail stores. They are used in conveyor systems for sorting, scanning, and transporting packages and products. Plastic belts offer smooth and reliable movement of items, facilitating efficient order fulfillment, inventory management, and store replenishment processes.

- 6. Automotive Industry:

In the automotive industry, plastic belts are employed for material handling tasks such as conveying automotive components, assemblies, and finished products. They are used in production lines for processes like painting, assembly, and testing. Plastic belts provide the necessary strength, flexibility, and wear resistance required to withstand the demanding conditions of automotive manufacturing.

These are just a few examples of the industries where plastic belts are commonly employed for material handling. Other industries such as textiles, electronics, agriculture, and mining also utilize plastic belts to streamline their material handling operations and improve overall efficiency.

editor by CX 2024-02-25

China Best Sales Custom V Groove Belt Pulley Plastic Idler Pulley Wheel electric axle

Product Description

Our Services

Product Design Material Selection

Mold Design Mold Making

Bulk Production Logo Printing

Surface Treatment Assembling

Packaging Door to Door Delivery

| Material | Nylon ,mc nylon, POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc. |

| Color | Black, white, red, green, transparent or any color according to Pantone code |

| Size | As per customer’s requirements |

| Technology | Injection molding, CNC machining, Extrusion |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

Detail Image

Why Choose Us

Our Machine

Product Range

Contact Us /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Pulley Sizes: | Type F |

|---|---|

| Manufacturing Process: | Casting |

| Material: | Plastic |

| Surface Treatment: | Customized |

| Item: | Plastic V Belt Pulley |

| Free Samples: | 1-5 PCS |

| Customization: |

Available

| Customized Request |

|---|

How do plastic belts contribute to reducing friction and energy consumption in conveyor systems?

Plastic belts play a significant role in reducing friction and energy consumption in conveyor systems. Here’s a detailed explanation:

- Low Coefficient of Friction:

Plastic belts are engineered to have a low coefficient of friction, which means they offer minimal resistance to the movement of conveyed materials. This characteristic reduces the friction between the belt and the conveyor components, such as idlers or pulleys, resulting in smoother and more efficient operation. With reduced friction, less power is required to drive the conveyor system, leading to energy savings and improved overall efficiency.

- Lightweight Construction:

Plastic belts are generally lightweight compared to other belt materials, such as rubber or metal. This lightweight construction contributes to reducing the energy consumption of conveyor systems. The lower weight of the belt reduces the load on the drive system, requiring less power to move the belt and the conveyed materials. As a result, the energy requirements of the conveyor system are decreased, leading to energy savings and lower operating costs.

- Reduced Belt-to-Belt Friction:

In conveyor systems where multiple belts are used, plastic belts can help reduce belt-to-belt friction. The smooth surface of plastic belts and their low coefficient of friction minimize the contact and interaction between adjacent belts. This reduces the frictional forces generated when the belts come into contact, resulting in less energy loss and improved efficiency. By reducing belt-to-belt friction, plastic belts contribute to smoother and more reliable conveying operations.

- Improved Belt Flexibility:

Plastic belts are designed to be flexible, allowing them to adapt to the contours of conveyor systems more effectively. The flexibility of plastic belts helps to maintain proper belt alignment and reduces the occurrence of misalignment-related friction. When a belt is misaligned, it can cause increased friction and wear on the belt and the conveyor components, leading to higher energy consumption. By promoting better belt alignment, plastic belts minimize frictional losses and contribute to energy efficiency.

- Efficient Transfer of Power:

Plastic belts offer efficient power transfer within the conveyor system. The low coefficient of friction and lightweight construction of plastic belts allow for more effective transmission of power from the drive system to the belt. This efficient transfer of power ensures that a greater portion of the energy input is utilized for moving the conveyed materials, rather than being lost as heat or wasted due to friction. As a result, the overall energy consumption of the conveyor system is reduced.

In summary, plastic belts contribute to reducing friction and energy consumption in conveyor systems through their low coefficient of friction, lightweight construction, reduced belt-to-belt friction, improved belt flexibility, and efficient transfer of power. These characteristics not only enhance the overall efficiency of the conveyor system but also result in energy savings and reduced operating costs. By choosing plastic belts, industries can optimize their conveyor operations, minimize energy usage, and achieve more sustainable and cost-effective material handling processes.

What role do plastic belts play in ensuring hygiene and cleanliness in food processing applications?

Plastic belts play a crucial role in ensuring hygiene and cleanliness in food processing applications. Here’s a detailed explanation:

- 1. Smooth, Non-Porous Surfaces:

Plastic belts used in food processing applications are designed with smooth, non-porous surfaces. These surfaces prevent the accumulation of food particles, liquids, or other contaminants, reducing the risk of bacterial growth and cross-contamination. Smooth surfaces also make it easier to clean the belts effectively, ensuring optimal hygiene standards are maintained.

- 2. Resistance to Moisture and Chemicals:

Plastic belts for food processing applications are resistant to moisture and a wide range of chemicals used in cleaning and sanitization processes. They can withstand frequent washdowns with water, detergents, and disinfectants without degrading or compromising their structural integrity. This resistance to moisture and chemicals contributes to the overall cleanliness and hygiene of the food processing environment.

- 3. Bacterial Growth Prevention:

Plastic belts inhibit bacterial growth due to their non-porous surfaces and resistance to moisture. Unlike fabric belts, which can absorb and retain moisture, plastic belts do not provide a favorable environment for bacteria to thrive. By minimizing bacterial growth, plastic belts help maintain the cleanliness and safety of food products during processing.

- 4. Compatibility with Sanitization Processes:

Plastic belts used in food processing applications are designed to withstand regular sanitization procedures. They can be easily cleaned using standard cleaning agents, high-pressure washdowns, or even steam cleaning. Plastic belts are resilient to the harsh chemicals and high temperatures often employed in food processing facilities for effective sanitization, ensuring that the belts themselves remain hygienic and do not become a source of contamination.

- 5. Compliance with Food Safety Standards:

Plastic belts used in the food processing industry are often manufactured from food-grade materials that comply with relevant safety regulations. These materials are chosen for their ability to meet strict food safety requirements, including FDA (Food and Drug Administration) or EU (European Union) regulations. By using plastic belts that meet these standards, food processors can ensure that their operations align with the necessary hygiene and safety guidelines.

- 6. Easy Maintenance and Inspection:

Plastic belts are relatively easy to maintain and inspect for cleanliness. Their smooth surfaces allow for quick visual inspection to detect any visible contamination or debris. If cleaning is required, plastic belts can be easily cleaned using appropriate methods, reducing downtime and allowing for efficient production processes.

In summary, plastic belts play a vital role in ensuring hygiene and cleanliness in food processing applications. Their smooth, non-porous surfaces, resistance to moisture and chemicals, prevention of bacterial growth, compatibility with sanitization processes, compliance with food safety standards, and ease of maintenance contribute to maintaining a clean and safe environment for food processing operations.

Can you describe the different types of plastic belts available in the market today?

There are several different types of plastic belts available in the market today, each designed to meet specific application requirements. Here’s an overview of some commonly used types:

- 1. Modular Plastic Belts:

Modular plastic belts consist of interlocking plastic modules or links that form a continuous belt. These belts offer flexibility, allowing them to navigate around corners, bends, and other obstacles smoothly. They are commonly used in applications that require accumulation, incline/decline conveying, or small product transfer. Modular plastic belts are available in various configurations, such as flat-top, flush-grid, and raised-rib designs, to accommodate different product types and handling requirements.

- 2. Solid Plastic Belts:

Solid plastic belts are made from a single piece of plastic material without interlocking modules. They offer a smooth and continuous surface, making them suitable for applications that require stable and consistent product conveying. Solid plastic belts are often used in industries such as food processing, where hygiene, easy cleaning, and resistance to contamination are crucial.

- 3. Cleated Plastic Belts:

Cleated plastic belts feature integrally molded cleats or projections on their surface. These cleats help to prevent product slippage and facilitate the inclined or vertical movement of bulk materials or packages. Cleated plastic belts are commonly used in applications such as incline or decline conveying, sorting, and elevating products in industries like agriculture, recycling, and manufacturing.

- 4. Wire Mesh Plastic Belts:

Wire mesh plastic belts consist of a plastic mesh overlaying metal or plastic rods. These belts offer an open and breathable surface, allowing for easy drainage, airflow, and visual inspection of conveyed products. They are often used in applications where heat, steam, or liquids need to pass through the belt, such as baking ovens, washing processes, or drying operations in the food industry.

- 5. Vacuum Plastic Belts:

Vacuum plastic belts are designed with a perforated or porous surface that allows the application of vacuum pressure to hold and stabilize lightweight or delicate products during conveying. These belts are commonly used in industries such as electronics, printing, and packaging, where precise positioning and gentle handling of products are required.

- 6. Anti-Static Plastic Belts:

Anti-static plastic belts are specifically designed to dissipate static electricity and prevent the buildup of electrostatic charges. They are used in applications where static discharge could damage sensitive electronic components or create safety hazards. Anti-static plastic belts are commonly employed in electronics manufacturing, semiconductor production, and cleanroom environments.

These are just a few examples of the different types of plastic belts available in the market today. The choice of plastic belt depends on factors such as the application requirements, load capacity, product characteristics, environmental conditions, and industry-specific regulations. Manufacturers often offer a range of customization options to tailor the belt design, material, and features to meet the specific needs of their customers.

editor by CX 2024-02-11

China OEM Custom V Groove Belt Pulley Plastic Idler Pulley Wheel axle shaft

Product Description

Our Services

Product Design Material Selection

Mold Design Mold Making

Bulk Production Logo Printing

Surface Treatment Assembling

Packaging Door to Door Delivery

| Material | Nylon ,mc nylon, POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc. |

| Color | Black, white, red, green, transparent or any color according to Pantone code |

| Size | As per customer’s requirements |

| Technology | Injection molding, CNC machining, Extrusion |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

Detail Image

Why Choose Us

Our Machine

Product Range

Contact Us /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Pulley Sizes: | Type F |

|---|---|

| Manufacturing Process: | Casting |

| Material: | Plastic |

| Surface Treatment: | Customized |

| Item: | Plastic V Belt Pulley |

| Free Samples: | 1-5 PCS |

| Customization: |

Available

| Customized Request |

|---|

Can plastic belts be used in heavy-duty applications, such as mining or construction?

Yes, plastic belts can indeed be used in heavy-duty applications, including mining and construction. Here’s a detailed explanation:

- Plastic Belt Advancements:

In recent years, there have been significant advancements in plastic belt technology, leading to the development of robust and high-performance plastic belts. These advancements include enhanced material formulations, reinforcement technologies, and improved belt designs, which have expanded the capabilities of plastic belts and made them suitable for heavy-duty applications.

- Strength and Load-Carrying Capacity:

Plastic belts designed for heavy-duty applications are engineered to have excellent strength and load-carrying capacity. Reinforcement technologies, such as embedded fibers, fabric layers, or metal cords, are incorporated into the belt structure to enhance tensile strength and dimensional stability. These reinforcements enable plastic belts to handle heavy loads, endure high tension levels, and resist elongation or stretching during operation. As a result, plastic belts can effectively convey bulk materials, aggregates, or heavy equipment in mining and construction environments.

- Wear and Impact Resistance:

Plastic belts used in heavy-duty applications are designed to exhibit superior wear and impact resistance. They are engineered to withstand the abrasive nature of mining operations or the harsh conditions encountered in construction sites. Advanced material formulations and surface coatings are employed to enhance the belt’s durability, preventing premature wear and tear caused by abrasive materials or impacts from heavy loads. This ensures that plastic belts can maintain their performance and reliability even in demanding operating conditions.

- Chemical and Moisture Resistance:

Plastic belts for heavy-duty applications in mining or construction often have excellent chemical and moisture resistance properties. They are designed to withstand exposure to various chemicals, oils, solvents, or moisture commonly found in these environments. This resistance prevents chemical degradation, swelling, or weakening of the belt material, ensuring its long-term performance and reliability. Additionally, plastic belts with moisture-resistant properties are less prone to damage from water or humidity, making them suitable for outdoor applications or environments with high moisture levels.

- Customization and Modular Designs:

Plastic belts offer customization options and modular designs that make them adaptable to the specific requirements of heavy-duty applications. Manufacturers provide a range of belt widths, lengths, and configurations to accommodate different conveyor systems and operational needs. The modular design of plastic belts allows for easy installation, repair, or replacement, minimizing downtime and ensuring continuous operation in mining or construction sites where efficiency is crucial.

- Benefits of Plastic Belts:

Using plastic belts in heavy-duty applications offers several advantages. Plastic belts are generally lightweight, which reduces the load on conveyor systems, lowers energy consumption, and simplifies installation and maintenance. They also have a lower coefficient of friction compared to other belt materials, resulting in reduced power requirements and improved conveyor efficiency. Additionally, plastic belts are resistant to rust, corrosion, and rot, making them suitable for outdoor or wet environments commonly encountered in mining and construction.

In summary, plastic belts can be successfully used in heavy-duty applications such as mining or construction. With advancements in material formulations, reinforcement technologies, and belt designs, plastic belts now offer the required strength, load-carrying capacity, wear resistance, and chemical resistance to withstand the demanding conditions of these industries. The customization options, modular designs, and additional benefits of plastic belts make them a reliable choice for efficient and durable conveying in heavy-duty applications.

Can plastic belts be customized for specific industries or conveyor configurations?

Yes, plastic belts can be customized to meet the specific requirements of different industries or conveyor configurations. Here’s a detailed explanation:

- 1. Industry-Specific Customization:

Plastic belt manufacturers understand that different industries have unique needs and operating conditions. Therefore, they offer customization options to tailor plastic belts to specific industry requirements. For example:

- In the food industry, plastic belts can be customized to meet stringent hygiene standards, such as having smooth surfaces for easy cleaning, being made from food-grade materials, or incorporating features like detectable materials for food safety.

- In the automotive industry, plastic belts can be customized to withstand high temperatures, resist oil and grease, and have enhanced durability to handle heavy loads.

- In the pharmaceutical industry, plastic belts can be customized to be resistant to chemicals, moisture, and microbial growth, ensuring compliance with strict regulatory requirements.

- In the packaging industry, plastic belts can be customized to have specific surface textures or patterns for efficient product transfer, or they can be designed with specialized attachments for precise product positioning or diverting.

- 2. Conveyor Configuration Customization:

Plastic belts can also be customized to match the specific conveyor configurations and requirements of individual applications. Conveyor systems come in various types, such as flatbed, roller, or modular conveyors, and may have unique characteristics or dimensions. Plastic belt manufacturers offer customization options to ensure a seamless fit with the conveyor system, including:

- Customized belt widths and lengths to match the dimensions of the conveyor system.

- Specialized belt designs, such as flat-top, flush-grid, or raised-rib configurations, based on the conveyor’s requirements for product stability, grip, or drainage.

- Customized belt accessories, such as sprockets, pulleys, or cleats, designed to work seamlessly with the conveyor system and provide the desired functionality.

- Modular plastic belts that can be easily assembled or reconfigured to fit different conveyor layouts or accommodate specific product handling needs.

Through industry-specific customization and conveyor configuration customization, plastic belts can be tailored to address the unique challenges and requirements of various industries and conveyor systems. This level of customization ensures optimal performance, efficiency, and reliability in material handling operations.

In what industries are plastic belts commonly employed for material handling?

Plastic belts are widely employed for material handling in various industries. Here’s a detailed explanation:

- 1. Food and Beverage Industry:

In the food and beverage industry, plastic belts are extensively used for material handling due to their hygienic properties, chemical resistance, and ease of cleaning. They are employed in applications such as conveying fruits, vegetables, baked goods, packaged foods, beverages, and dairy products. Plastic belts ensure safe and efficient transportation of food items while adhering to strict hygiene standards and preventing contamination.

- 2. Packaging and Logistics Industry:

Plastic belts find wide application in the packaging and logistics industry for the movement of packages, parcels, and containers. They are used in conveyor systems for sorting, merging, diverting, and accumulating packages during packaging, warehousing, and distribution processes. Plastic belts offer high strength, flexibility, and durability, allowing efficient handling of various package sizes and shapes.

- 3. Manufacturing and Assembly Industry:

In manufacturing and assembly processes, plastic belts are commonly employed for material handling tasks. They facilitate the transportation of components, parts, and products between different stages of production lines. Plastic belts can handle heavy loads, endure high-speed operations, and navigate through complex layouts, making them suitable for applications in automotive, electronics, appliances, and other manufacturing sectors.

- 4. Pharmaceutical and Healthcare Industry:

The pharmaceutical and healthcare industry relies on plastic belts for material handling in various stages of production, including drug manufacturing, packaging, and distribution. Plastic belts offer chemical resistance, easy cleanability, and compliance with industry regulations. They are used for conveying vials, bottles, blister packs, medical devices, and other pharmaceutical products in a controlled and hygienic environment.

- 5. E-commerce and Retail Industry:

Plastic belts play a vital role in the e-commerce and retail industry for material handling in distribution centers, fulfillment centers, and retail stores. They are used in conveyor systems for sorting, scanning, and transporting packages and products. Plastic belts offer smooth and reliable movement of items, facilitating efficient order fulfillment, inventory management, and store replenishment processes.

- 6. Automotive Industry:

In the automotive industry, plastic belts are employed for material handling tasks such as conveying automotive components, assemblies, and finished products. They are used in production lines for processes like painting, assembly, and testing. Plastic belts provide the necessary strength, flexibility, and wear resistance required to withstand the demanding conditions of automotive manufacturing.

These are just a few examples of the industries where plastic belts are commonly employed for material handling. Other industries such as textiles, electronics, agriculture, and mining also utilize plastic belts to streamline their material handling operations and improve overall efficiency.

editor by CX 2024-01-16

China Custom Manufacture ODM&OEM Red PU Nylon PA66 Plastic Roller Wheels Flat Pulley manufacturer

Product Description

Product Details

Description

- OEM size suit for customers’ requirment

- Multiple color can be choosed

- Engraved or embossed logo accepted

- Large order quantity are CZPT to be fulfilled

- Strict quality control system

- In time delivery and thoughtful custom-service

- Certification: SGS, GB/T 19001-2016, ISO9001:2005

| material | Nylon ,mc,nylon,POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc. |

| color | Black, white, red, green, transparent or any color according to Pantone code |

| size | As per customer’s requirements |

| Technology | Injection molding, CNC machining, Extrusion. |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

Our Factory

Customization Capabilities

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Pulley Sizes: | Type D |

|---|---|

| Manufacturing Process: | Forging |

| Material: | Plastic |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | Order Sample Custom packaging, consult us for sample price

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Are there sustainability aspects associated with the use of plastic belts in conveyor systems?

Plastic belts in conveyor systems can have both positive and negative sustainability aspects. Here’s a detailed explanation:

- Positive Sustainability Aspects:

Plastic belts offer several sustainability benefits when used in conveyor systems:

- 1. Energy Efficiency:

Plastic belts contribute to energy efficiency in conveyor systems. Their low coefficient of friction and lightweight construction require less power to drive the belts, resulting in reduced energy consumption. By minimizing energy requirements, plastic belts help conserve energy resources and reduce greenhouse gas emissions associated with energy generation.

- 2. Reduced Material Waste:

Plastic belts are typically designed for long-lasting performance and durability. They can withstand wear, abrasion, and exposure to various environments, resulting in extended service life. This longevity reduces the need for frequent belt replacements, minimizing material waste and reducing the environmental impact of manufacturing new belts.

- 3. Recyclability:

Many plastic belts used in conveyor systems are recyclable. At the end of their life cycle, these belts can be collected, processed, and recycled into new plastic products. Recycling plastic belts helps divert waste from landfills and reduces the demand for virgin materials, contributing to a more circular and sustainable economy.

- 4. Lightweight Design:

Plastic belts are lightweight compared to other belt materials like steel or rubber. This lightweight design reduces the overall weight of the conveyor system and the energy required to move the belts and conveyed materials. It also allows for easier installation and maintenance, reducing the need for heavy machinery and associated energy consumption.

- Negative Sustainability Aspects:

While plastic belts offer sustainability benefits, there are also negative aspects to consider:

- 1. Environmental Impact of Plastic:

Plastic belts are made from petroleum-based materials, and their production contributes to the extraction of fossil fuels and the emission of greenhouse gases. Additionally, if plastic belts are not properly managed at the end of their life cycle, they can end up in landfills or as litter, posing environmental challenges. To mitigate these negative aspects, it is crucial to promote responsible waste management practices, including recycling or proper disposal of plastic belts.

- 2. Chemical and Resource Intensity:

The manufacturing process of plastic belts can involve the use of chemicals and resources, including energy and water. The extraction and processing of these resources can have environmental impacts, such as pollution and resource depletion. To address this, manufacturers can adopt more sustainable production practices, including the use of eco-friendly materials, energy-efficient manufacturing processes, and responsible water management.

- 3. End-of-Life Management:

The disposal of plastic belts at the end of their life cycle can pose challenges if proper recycling infrastructure is lacking. If not recycled, the belts may end up in landfills, contributing to waste accumulation. To overcome this, it is important to establish and promote recycling programs for plastic belts, ensure accessibility to recycling facilities, and encourage the development of innovative recycling technologies.

In summary, the use of plastic belts in conveyor systems has sustainability aspects. Plastic belts offer energy efficiency, reduced material waste, recyclability, and lightweight design. However, the environmental impact of plastic, chemical and resource intensity in production, and proper end-of-life management should be considered to mitigate the negative aspects associated with plastic belt use. By adopting sustainable practices throughout the lifecycle of plastic belts, such as recycling and responsible manufacturing, the overall sustainability of conveyor systems can be improved.

Can you provide examples of products or machinery that utilize plastic belts for conveying purposes?

Many products and machinery across various industries utilize plastic belts for conveying purposes. Here are some examples:

- 1. Conveyor Systems:

Plastic belts are extensively used in conveyor systems across different industries. These systems can be found in manufacturing facilities, warehouses, distribution centers, airports, and more. Conveyor systems equipped with plastic belts are employed for the transportation of a wide range of products, including packaged goods, automotive components, electronics, pharmaceuticals, food items, and beverages.

- 2. Food Processing Equipment:

In the food processing industry, various equipment utilizes plastic belts for conveying purposes. Examples include food sorting and grading machines, washing and cleaning systems, baking ovens, cooling and freezing tunnels, and packaging lines. Plastic belts are chosen for their hygienic properties, easy cleanability, and ability to withstand the rigorous demands of food processing environments.

- 3. Bottling and Packaging Machinery:

Bottling and packaging machinery extensively employ plastic belts for efficient product handling and packaging. Equipment such as filling machines, capping machines, labelers, cartoners, and case packers utilize plastic belts to transport bottles, containers, boxes, and other packaging materials. Plastic belts allow for smooth and precise conveying, ensuring accurate positioning and high-speed operations in the bottling and packaging processes.

- 4. Automated Material Handling Systems:

Automated material handling systems, commonly used in industries such as automotive, electronics, and e-commerce, rely on plastic belts for conveying and sorting purposes. These systems utilize plastic belts to transport products between different stages of the production line, sort items based on various criteria, and load or unload materials in warehouses or distribution centers. Plastic belts enable efficient and reliable material handling in these automated systems.

- 5. Printing and Paper Handling Equipment:

Printing presses, bindery equipment, and paper handling machines often incorporate plastic belts for the smooth movement of paper sheets, printed materials, or packaging components. Plastic belts with anti-static properties are particularly used in these applications to prevent static buildup and ensure the safe handling of sensitive materials.

- 6. Cleanroom and Electronics Manufacturing Equipment:

Cleanroom environments and electronics manufacturing facilities utilize plastic belts for conveying delicate electronic components, circuit boards, and semiconductors. Plastic belts with low particulate generation and excellent cleanroom compatibility are crucial in these industries to maintain strict cleanliness standards and prevent contamination or damage to sensitive electronic devices.

These are just a few examples of products and machinery that utilize plastic belts for conveying purposes. Plastic belts offer versatility, reliability, and customization options, making them suitable for a wide range of applications across various industries.

What are plastic belts, and how are they used in various industries?

Plastic belts, also known as polymer belts or synthetic belts, are conveyor belts made from various types of plastic materials. These belts are used in a wide range of industries for conveying, transporting, or processing materials or products. Plastic belts offer several advantages over traditional belt materials such as rubber or fabric, including durability, versatility, and ease of maintenance. Here’s a detailed explanation of plastic belts and their applications in various industries:

- Composition and Construction:

- Food and Beverage Industry:

- Automotive Industry:

- Packaging and Logistics:

- Agriculture and Horticulture:

- Other Industries:

Plastic belts are typically made from materials such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polyurethane (PU), or acetal (POM). These materials provide properties such as high strength, chemical resistance, low friction, and flexibility. Plastic belts are manufactured through processes like extrusion, injection molding, or bonding, resulting in a wide variety of belt types, including flat belts, modular belts, timing belts, and conveyor chains.

Plastic belts find extensive use in the food and beverage industry. They are employed in applications such as food processing, packaging, sorting, and transportation. Plastic belts are preferred in these industries due to their hygienic properties, resistance to moisture and chemicals, and ease of cleaning. They are commonly used in conveying and sorting systems for products like fruits, vegetables, baked goods, meat, poultry, and beverages.

In the automotive industry, plastic belts are utilized for various purposes. They are employed in assembly lines for transporting automotive components during the manufacturing process. Plastic belts with specialized features, such as high temperature resistance or static dissipation properties, are used in applications like paint shops, heat treatment processes, or electrostatic discharge-sensitive areas. Plastic belts provide reliable and efficient material handling solutions in automotive production facilities.

Plastic belts play a crucial role in packaging and logistics operations. They are used in conveyor systems for handling packages, cartons, boxes, or containers in industries such as e-commerce, retail, distribution centers, and postal services. Plastic belts offer smooth and reliable transportation, enabling efficient sorting, merging, diverging, and accumulation of items. Their flexibility and customization options make them suitable for a wide range of packaging and logistics applications.

In the agriculture and horticulture industries, plastic belts are employed for tasks like seed sorting, crop harvesting, and greenhouse operations. Plastic belts with specialized features like perforations or airflow patterns are used to facilitate the handling and processing of seeds, fruits, vegetables, or flowers. They provide gentle and efficient transportation, reducing damage to delicate agricultural products and improving productivity in these sectors.

Plastic belts find applications in various other industries as well. They are used in industries such as pharmaceuticals, electronics, textile manufacturing, recycling, and airport baggage handling. Plastic belts offer advantages like chemical resistance, anti-static properties, and low noise levels, making them suitable for specific requirements in these industries.

In summary, plastic belts are conveyor belts made from plastic materials and are widely used in various industries. They offer durability, versatility, and ease of maintenance, making them suitable for applications in food and beverage processing, automotive manufacturing, packaging and logistics, agriculture and horticulture, and many other sectors. Plastic belts provide efficient material handling solutions, ensuring smooth transportation, sorting, and processing of products or materials in diverse industrial settings.

editor by CX 2024-01-09

China Custom Manufacture ODM&OEM Red PU Nylon PA66 Plastic Roller Wheels Flat Pulley axle shaft

Product Description

Product Details

Description

- OEM size suit for customers’ requirment

- Multiple color can be choosed

- Engraved or embossed logo accepted

- Large order quantity are CZPT to be fulfilled

- Strict quality control system

- In time delivery and thoughtful custom-service

- Certification: SGS, GB/T 19001-2016, ISO9001:2005

| material | Nylon ,mc,nylon,POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc. |

| color | Black, white, red, green, transparent or any color according to Pantone code |

| size | As per customer’s requirements |

| Technology | Injection molding, CNC machining, Extrusion. |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

Our Factory

Customization Capabilities

| Pulley Sizes: | Type D |

|---|---|

| Manufacturing Process: | Forging |

| Material: | Plastic |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | Order Sample Custom packaging, consult us for sample price

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you provide insights into the future trends and developments in plastic belt technology for industrial conveyance?

Plastic belt technology for industrial conveyance is continuously evolving, driven by advancements in materials science, manufacturing processes, and industry demands. Here are some insights into the future trends and developments in plastic belt technology:

- 1. Enhanced Material Formulations:

Future developments in plastic belt technology will likely involve the development of advanced material formulations with improved properties. Manufacturers are investing in research and development to enhance the strength, durability, and wear resistance of plastic belts. These developments may include the use of new polymers, additives, and reinforcement materials to create belts that can withstand higher loads, temperatures, and abrasive environments.

- 2. Increased Customization:

Customization is becoming a significant trend in plastic belt technology. Conveyor systems are used in a wide range of industries with varying requirements, and customization allows for tailored solutions. In the future, plastic belt manufacturers may offer a wider range of customization options, such as belt width, surface patterns, and specialized coatings, to meet specific application needs. This trend will enable optimized performance, improved efficiency, and reduced maintenance for industrial conveyance systems.

- 3. Integration of Smart Technologies:

Smart technologies are increasingly being integrated into industrial systems, and plastic belt technology is no exception. In the future, plastic belts may incorporate sensors, data collection devices, and connectivity features to enable real-time monitoring and analysis of belt performance. This integration of smart technologies will allow for predictive maintenance, early fault detection, and optimization of conveyor system efficiency. The data collected from the belts can be used to optimize operations, reduce downtime, and improve overall productivity.

- 4. Focus on Sustainability:

Sustainability is a growing concern in the industrial sector, and future developments in plastic belt technology will likely reflect this trend. Manufacturers are exploring ways to reduce the environmental impact of plastic belts by incorporating recycled materials, adopting more sustainable manufacturing processes, and improving end-of-life management. Additionally, there may be an increased emphasis on designing belts that are lighter in weight, energy-efficient, and recyclable, thus further enhancing the sustainability profile of plastic belt technology.

- 5. Advancements in Joining and Splicing Techniques:

The joining and splicing of plastic belts are critical for creating a continuous and reliable conveyor system. Future developments may focus on advancements in joining and splicing techniques to improve the strength, flexibility, and longevity of belt connections. This can involve the development of new bonding agents, welding methods, or mechanical fastening systems that provide stronger and more durable belt joints. These advancements will contribute to the overall performance and reliability of plastic belt technology in industrial conveyance.

In summary, the future of plastic belt technology for industrial conveyance is expected to witness advancements in material formulations, increased customization options, integration of smart technologies, a focus on sustainability, and improvements in joining and splicing techniques. These developments will drive enhanced performance, efficiency, and sustainability of conveyor systems, meeting the evolving needs of industries across various sectors.

Can plastic belts be customized for specific industries or conveyor configurations?

Yes, plastic belts can be customized to meet the specific requirements of different industries or conveyor configurations. Here’s a detailed explanation:

- 1. Industry-Specific Customization:

Plastic belt manufacturers understand that different industries have unique needs and operating conditions. Therefore, they offer customization options to tailor plastic belts to specific industry requirements. For example:

- In the food industry, plastic belts can be customized to meet stringent hygiene standards, such as having smooth surfaces for easy cleaning, being made from food-grade materials, or incorporating features like detectable materials for food safety.

- In the automotive industry, plastic belts can be customized to withstand high temperatures, resist oil and grease, and have enhanced durability to handle heavy loads.

- In the pharmaceutical industry, plastic belts can be customized to be resistant to chemicals, moisture, and microbial growth, ensuring compliance with strict regulatory requirements.

- In the packaging industry, plastic belts can be customized to have specific surface textures or patterns for efficient product transfer, or they can be designed with specialized attachments for precise product positioning or diverting.

- 2. Conveyor Configuration Customization:

Plastic belts can also be customized to match the specific conveyor configurations and requirements of individual applications. Conveyor systems come in various types, such as flatbed, roller, or modular conveyors, and may have unique characteristics or dimensions. Plastic belt manufacturers offer customization options to ensure a seamless fit with the conveyor system, including:

- Customized belt widths and lengths to match the dimensions of the conveyor system.

- Specialized belt designs, such as flat-top, flush-grid, or raised-rib configurations, based on the conveyor’s requirements for product stability, grip, or drainage.

- Customized belt accessories, such as sprockets, pulleys, or cleats, designed to work seamlessly with the conveyor system and provide the desired functionality.

- Modular plastic belts that can be easily assembled or reconfigured to fit different conveyor layouts or accommodate specific product handling needs.

Through industry-specific customization and conveyor configuration customization, plastic belts can be tailored to address the unique challenges and requirements of various industries and conveyor systems. This level of customization ensures optimal performance, efficiency, and reliability in material handling operations.

In what industries are plastic belts commonly employed for material handling?

Plastic belts are widely employed for material handling in various industries. Here’s a detailed explanation:

- 1. Food and Beverage Industry:

In the food and beverage industry, plastic belts are extensively used for material handling due to their hygienic properties, chemical resistance, and ease of cleaning. They are employed in applications such as conveying fruits, vegetables, baked goods, packaged foods, beverages, and dairy products. Plastic belts ensure safe and efficient transportation of food items while adhering to strict hygiene standards and preventing contamination.

- 2. Packaging and Logistics Industry:

Plastic belts find wide application in the packaging and logistics industry for the movement of packages, parcels, and containers. They are used in conveyor systems for sorting, merging, diverting, and accumulating packages during packaging, warehousing, and distribution processes. Plastic belts offer high strength, flexibility, and durability, allowing efficient handling of various package sizes and shapes.

- 3. Manufacturing and Assembly Industry:

In manufacturing and assembly processes, plastic belts are commonly employed for material handling tasks. They facilitate the transportation of components, parts, and products between different stages of production lines. Plastic belts can handle heavy loads, endure high-speed operations, and navigate through complex layouts, making them suitable for applications in automotive, electronics, appliances, and other manufacturing sectors.

- 4. Pharmaceutical and Healthcare Industry:

The pharmaceutical and healthcare industry relies on plastic belts for material handling in various stages of production, including drug manufacturing, packaging, and distribution. Plastic belts offer chemical resistance, easy cleanability, and compliance with industry regulations. They are used for conveying vials, bottles, blister packs, medical devices, and other pharmaceutical products in a controlled and hygienic environment.

- 5. E-commerce and Retail Industry:

Plastic belts play a vital role in the e-commerce and retail industry for material handling in distribution centers, fulfillment centers, and retail stores. They are used in conveyor systems for sorting, scanning, and transporting packages and products. Plastic belts offer smooth and reliable movement of items, facilitating efficient order fulfillment, inventory management, and store replenishment processes.

- 6. Automotive Industry:

In the automotive industry, plastic belts are employed for material handling tasks such as conveying automotive components, assemblies, and finished products. They are used in production lines for processes like painting, assembly, and testing. Plastic belts provide the necessary strength, flexibility, and wear resistance required to withstand the demanding conditions of automotive manufacturing.

These are just a few examples of the industries where plastic belts are commonly employed for material handling. Other industries such as textiles, electronics, agriculture, and mining also utilize plastic belts to streamline their material handling operations and improve overall efficiency.

editor by CX 2023-11-20

China Good quality Custom CNC Machining CNC Machined Aluminum Adjustable Cam Timing Gear Pulley with Great quality

Product Description

Company Profile

Workshop

Detailed Photos

Product Description

| Material | Alloy Steel, Copper alloy(brass,silicon bronze,phosphor bronze,aluminum bronze,beryllium copper),Stainless Steel,Aluminum,Titanium, Magnesium, Superalloys,Molybdenum, Invar,,Zinc,Tungsten steel,incoloy,Nickel 200,Hastelloy, Inconel,Monel,ABS, PEEK,PTFE,PVC,Acetal. |

| Surface Treatment | Zn-plating, Ni-plating, Cr-plating, Tin-plating, copper-plating, the wreath oxygen resin spraying, the heat disposing, hot-dip galvanizing, black oxide coating, painting, powdering, color zinc-plated, blue black zinc-plated, rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing etc. |

| Producing Equipment | CNC machine,automatic lathe machine,CNC milling machine,lasering,tag grinding machine etc. |

| Drawing Format | Pro/E, Auto CAD, CZPT Works, UG, CAD/CAM, PDF |

| Managing Returned Goods | With quality problem or deviation from drawings |

| Warranty | Replacement at all our cost for rejected products |

| Main Markets | North America, South America, Eastern Europe , West Europe , North Europe, South Europe, Asia |

| How to order | * You send us drawing or sample |

| * We carry through project assessment | |

| * We make the sample and send it to you after you confirmed our design | |

| * You confirm the sample then place an order and pay us 30% deposit | |

| * We start producing | |

| * When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers. | |

| * Trade is done, thank you!! |

Quality Control

Packaging & Shipping

Customer Reviews

FAQ