Product Description

1. More than10 years manufacture in packing machine

2. 10 years alibaba supplier

3. 100% QC inspection before shipment

4. 12 months warranty

5. Product Certificated by CE

Introduction:

ARLM-160A Automatic Labeling Machine can meet the needs of semi circle labeling, bottle labeling switching between simple, convenient adjustment;

Wide application range: self-adhesive labels, adhesive film, electronic monitoring code, bar code etc..

Application Industry: widely used in food, medicine, cosmetics, daily chemical, electronics, hardware, plastics and other industries.

Application example: PET round bottle labeling, plastic bottle labeling, canned food, etc.

Features:

1. Labeling quality, using standard of spring cover belt, labeling smooth, no wrinkles, improve packaging quality.

2. Flexible application, bottle stand vertical labeling, with automatic sub bottle function, can be stand-alone production, can also be connected to the production line.

3. Intelligent control, automatic photoelectric tracking, with no matter no labeling, no standard automatic calibration and label automatic detection function, prevent leakage and label waste.

4. Simple adjustment, labeling speed, conveying speed, bottle speed can be achieved stepless speed regulation, according to the need to adjust.

5. Durable, using 3 bar adjustment mechanism, make full use of triangular stability, solid durable machine. Made of stainless steel and advanced aluminum alloy, accord with CE Production requirements.

Customized Functions:

1. Can add coding,printing

2. The conveyor can be replaced with a chain plate

3. The width,length,hight can be customize

4. The custom function is applicable to all automatic labeling machines

5. The machine can only be used to sticker labels, can be customized to stick transparent labels, need to change the optical fiber to transparent optical fiber.(Conventional label by induction color; Transparent label by induction thickness)

Note:

This machine is standard machine, can only be used normal round bottles , can not be too soft or bulge.

Can be customized if the bottle has grooves.

Parameter:

| Model | ARLM-160A |

| Power | 550W |

| Filling speed | 10-50PCS/min |

| Filling accuracy | ±1% |

| Bottle diameter | 30-150mm |

| Bottle high | 10-500mm |

| Lable Weight | 20-150mm |

| Lable Hight | 30-160mm |

Q: Are you a factory or a trading company?

A: We are factory manufacturing packaging machines and weprovide perfect OEM and after-sale service.

Q: Can you send me the video to show how the machine works?

A: Certainly, we have made video of every machine and uploaded them to Youtube.

Q: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you.

Q: How can I know your machine is designed for my product?

A: You can send us samples of your product and we test it on machine.

Q: How can I pay my order?

A: We accept T/T, L/C paying methods. For those orders less than 500USD, we accept Trade Assurance to pay.

Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.

Your Satisfaction is Our Honor

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Automatic Grade: | Automatic |

|---|---|

| Applicable Industry: | Food, Cosmetics, Agriculture, Medicine, Daily Chem |

| Application: | Cosmetics, Drinks, Cleaning, Detergent, Skin Care Products, Hair Care Products, Oil, Tea, Fish, Meat, Snack, Seasoning, Dairy Products |

| Type: | Automatic Labeling Machine |

| Driven Type: | Electric |

| Classification: | Automatic Vertical Round Bottle Labeling Machine |

| Customization: |

Available

| Customized Request |

|---|

How do plastic belts contribute to reducing friction and energy consumption in conveyor systems?

Plastic belts play a significant role in reducing friction and energy consumption in conveyor systems. Here’s a detailed explanation:

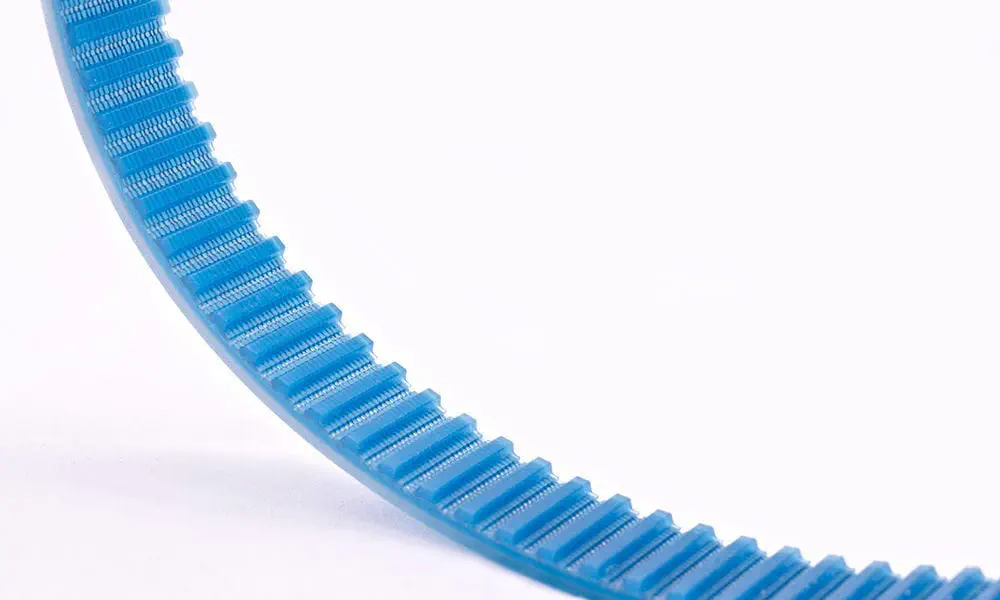

- Low Coefficient of Friction:

Plastic belts are engineered to have a low coefficient of friction, which means they offer minimal resistance to the movement of conveyed materials. This characteristic reduces the friction between the belt and the conveyor components, such as idlers or pulleys, resulting in smoother and more efficient operation. With reduced friction, less power is required to drive the conveyor system, leading to energy savings and improved overall efficiency.

- Lightweight Construction:

Plastic belts are generally lightweight compared to other belt materials, such as rubber or metal. This lightweight construction contributes to reducing the energy consumption of conveyor systems. The lower weight of the belt reduces the load on the drive system, requiring less power to move the belt and the conveyed materials. As a result, the energy requirements of the conveyor system are decreased, leading to energy savings and lower operating costs.

- Reduced Belt-to-Belt Friction:

In conveyor systems where multiple belts are used, plastic belts can help reduce belt-to-belt friction. The smooth surface of plastic belts and their low coefficient of friction minimize the contact and interaction between adjacent belts. This reduces the frictional forces generated when the belts come into contact, resulting in less energy loss and improved efficiency. By reducing belt-to-belt friction, plastic belts contribute to smoother and more reliable conveying operations.

- Improved Belt Flexibility:

Plastic belts are designed to be flexible, allowing them to adapt to the contours of conveyor systems more effectively. The flexibility of plastic belts helps to maintain proper belt alignment and reduces the occurrence of misalignment-related friction. When a belt is misaligned, it can cause increased friction and wear on the belt and the conveyor components, leading to higher energy consumption. By promoting better belt alignment, plastic belts minimize frictional losses and contribute to energy efficiency.

- Efficient Transfer of Power:

Plastic belts offer efficient power transfer within the conveyor system. The low coefficient of friction and lightweight construction of plastic belts allow for more effective transmission of power from the drive system to the belt. This efficient transfer of power ensures that a greater portion of the energy input is utilized for moving the conveyed materials, rather than being lost as heat or wasted due to friction. As a result, the overall energy consumption of the conveyor system is reduced.

In summary, plastic belts contribute to reducing friction and energy consumption in conveyor systems through their low coefficient of friction, lightweight construction, reduced belt-to-belt friction, improved belt flexibility, and efficient transfer of power. These characteristics not only enhance the overall efficiency of the conveyor system but also result in energy savings and reduced operating costs. By choosing plastic belts, industries can optimize their conveyor operations, minimize energy usage, and achieve more sustainable and cost-effective material handling processes.

How does the durability of plastic belts compare to other materials in conveyor systems?

When comparing the durability of plastic belts to other materials used in conveyor systems, several factors come into play. Here’s a detailed explanation:

- 1. Wear Resistance:

Plastic belts generally offer good wear resistance, allowing them to withstand the demands of many industrial applications. The specific wear resistance can vary depending on the type of plastic material used for the belt. Some plastic materials, such as polyurethane (PU) or acetal (POM), exhibit excellent wear resistance and can withstand abrasive environments better than other materials like fabric or rubber belts. However, in high-intensity applications with heavy loads or sharp objects, metal belts may provide superior wear resistance compared to plastic belts.

- 2. Impact Resistance:

Plastic belts typically have good impact resistance, especially when compared to rigid materials like metal belts. Plastic belts can absorb and dissipate impact forces, reducing the risk of damage or breakage. This makes plastic belts suitable for applications where the conveyed products may encounter impacts during loading, unloading, or handling processes. However, in extremely demanding applications with heavy or sharp impacts, specialized metal belts or reinforced fabric belts may offer higher impact resistance than plastic belts.

- 3. Chemical Resistance:

Plastic belts generally exhibit excellent chemical resistance compared to other materials like fabric or rubber belts. They can withstand exposure to a wide range of chemicals, oils, solvents, and cleaning agents without significant degradation. This makes plastic belts suitable for industries where corrosive substances or chemical cleaning agents are present. In contrast, fabric or rubber belts may deteriorate or experience chemical damage when exposed to aggressive substances.

- 4. Moisture Resistance:

Plastic belts are highly resistant to moisture, making them suitable for applications in wet environments or where frequent washdowns are required. Unlike fabric belts that can absorb moisture and become weakened, plastic belts maintain their structural integrity and performance even when exposed to water or high humidity. Metal belts, on the other hand, may be prone to corrosion when exposed to moisture, requiring additional protective measures.

- 5. Temperature Resistance:

The temperature resistance of plastic belts can vary depending on the specific plastic material used. Some plastic materials, such as polypropylene (PP) or polyethylene (PE), have lower temperature resistance compared to other materials like metal belts. However, there are plastic belt options available, such as polyurethane (PU) or polyvinyl chloride (PVC), that offer high-temperature resistance and can withstand elevated temperatures in industrial applications. It’s essential to select a plastic belt that matches the temperature range of the intended application.

- 6. Longevity and Maintenance:

The longevity and maintenance requirements of plastic belts can be favorable compared to other materials. Plastic belts typically have a longer lifespan than fabric belts, as they are less prone to fraying, tearing, or stretching. They also require minimal maintenance, as they do not need regular lubrication or tension adjustments like metal belts. Plastic belts can be easily cleaned and sanitized, prolonging their service life. However, metal belts may offer exceptional longevity and require minimal maintenance as well.

In summary, plastic belts offer good durability in many industrial applications, particularly when it comes to wear resistance, impact resistance, chemical resistance, moisture resistance, and ease of maintenance. However, in certain demanding applications with heavy loads, sharp impacts, or extreme temperatures, specialized metal belts or reinforced fabric belts may provide superior durability. It’s crucial to assess the specific requirements of the application and select the most appropriate belt material based on the expected operating conditions and the desired level of durability.

How do plastic belts contribute to the efficiency and functionality of conveyor systems?

Plastic belts play a crucial role in enhancing the efficiency and functionality of conveyor systems. Here’s a detailed explanation:

- 1. Lightweight and High Strength:

Plastic belts are typically lightweight yet offer high strength and load-carrying capacity. Their lightweight nature reduces the overall weight of the conveyor system, resulting in lower energy consumption and reduced strain on the system’s components. Despite their lightness, plastic belts can handle heavy loads, making them suitable for a wide range of applications while maintaining efficiency and functionality.

- 2. Flexibility and Adaptability:

Plastic belts are highly flexible and adaptable, allowing them to conform to the shape of the conveyor system. This flexibility enables the belts to navigate around pulleys, curves, and other obstacles smoothly. It also facilitates easy installation and adjustment of the conveyor system, making it more versatile and accommodating to different layout configurations. The adaptability of plastic belts contributes to efficient material handling and optimized system functionality.

- 3. Low Friction and Energy Efficiency:

Plastic belts have low friction characteristics, which significantly reduce energy consumption in conveyor systems. The low coefficient of friction between the belt and the conveyor components minimizes resistance and allows for smooth movement of materials. This low friction property not only enhances the efficiency of the system but also reduces wear and tear on the belt and other system components, leading to extended service life and reduced maintenance requirements.

- 4. Chemical Resistance and Hygiene:

Plastic belts are often resistant to chemicals, oils, and other substances, making them suitable for conveying materials in various industries, including food processing, pharmaceuticals, and manufacturing. Their chemical resistance ensures that the belts can withstand exposure to corrosive or potentially harmful substances without degradation or contamination. Additionally, plastic belts can be easily cleaned and sanitized, promoting hygiene and meeting strict industry standards in applications where cleanliness is essential.

- 5. Noise Reduction:

Compared to traditional conveyor belts made of materials like metal or rubber, plastic belts offer noise reduction benefits. Plastic belts produce less noise during operation due to their inherent damping properties. This noise reduction is especially advantageous in environments where noise levels need to be minimized, such as in retail settings or sensitive manufacturing processes, contributing to a quieter and more comfortable work environment.

- 6. Durability and Longevity:

Plastic belts are known for their durability and longevity. They are resistant to wear, abrasion, and impact, ensuring reliable and long-lasting performance in demanding conveyor applications. Plastic belts are less susceptible to damage from moisture, temperature variations, and other environmental factors, which can compromise the functionality of other belt materials. Their durability and longevity contribute to increased uptime, reduced downtime, and overall cost savings in conveyor system operation.

In summary, plastic belts offer several advantages that contribute to the efficiency and functionality of conveyor systems. Their lightweight yet high-strength construction, flexibility and adaptability, low friction characteristics, chemical resistance, noise reduction properties, and durability make them valuable components in a wide range of industries. By utilizing plastic belts, conveyor systems can achieve improved material handling efficiency, reduced energy consumption, enhanced hygiene, minimized maintenance requirements, and extended service life.

editor by CX 2024-02-23

China Custom Hzpk Arlm-160A Glass Jar Automatic Bottle Labeling Machine Small with Great quality

Product Description

1. More than10 years manufacture in packing machine

2. 10 years alibaba supplier

3. 100% QC inspection before shipment

4. 12 months warranty

5. Product Certificated by CE

Introduction:

ARLM-160A Automatic Labeling Machine can meet the needs of semi circle labeling, bottle labeling switching between simple, convenient adjustment;

Wide application range: self-adhesive labels, adhesive film, electronic monitoring code, bar code etc..

Application Industry: widely used in food, medicine, cosmetics, daily chemical, electronics, hardware, plastics and other industries.

Application example: PET round bottle labeling, plastic bottle labeling, canned food, etc.

Features:

1. Labeling quality, using standard of spring cover belt, labeling smooth, no wrinkles, improve packaging quality.

2. Flexible application, bottle stand vertical labeling, with automatic sub bottle function, can be stand-alone production, can also be connected to the production line.

3. Intelligent control, automatic photoelectric tracking, with no matter no labeling, no standard automatic calibration and label automatic detection function, prevent leakage and label waste.

4. Simple adjustment, labeling speed, conveying speed, bottle speed can be achieved stepless speed regulation, according to the need to adjust.

5. Durable, using 3 bar adjustment mechanism, make full use of triangular stability, solid durable machine. Made of stainless steel and advanced aluminum alloy, accord with CE Production requirements.

Customized Functions:

1. Can add coding,printing

2. The conveyor can be replaced with a chain plate

3. The width,length,hight can be customize

4. The custom function is applicable to all automatic labeling machines

5. The machine can only be used to sticker labels, can be customized to stick transparent labels, need to change the optical fiber to transparent optical fiber.(Conventional label by induction color; Transparent label by induction thickness)

Note:

This machine is standard machine, can only be used normal round bottles , can not be too soft or bulge.

Can be customized if the bottle has grooves.

Parameter:

| Model | ARLM-160A |

| Power | 550W |

| Filling speed | 10-50PCS/min |

| Filling accuracy | ±1% |

| Bottle diameter | 30-150mm |

| Bottle high | 10-500mm |

| Lable Weight | 20-150mm |

| Lable Hight | 30-160mm |

Q: Are you a factory or a trading company?

A: We are factory manufacturing packaging machines and weprovide perfect OEM and after-sale service.

Q: Can you send me the video to show how the machine works?

A: Certainly, we have made video of every machine and uploaded them to Youtube.

Q: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you.

Q: How can I know your machine is designed for my product?

A: You can send us samples of your product and we test it on machine.

Q: How can I pay my order?

A: We accept T/T, L/C paying methods. For those orders less than 500USD, we accept Trade Assurance to pay.

Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.

Your Satisfaction is Our Honor

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Automatic Grade: | Automatic |

|---|---|

| Applicable Industry: | Food, Cosmetics, Agriculture, Medicine, Daily Chem |

| Application: | Cosmetics, Drinks, Cleaning, Detergent, Skin Care Products, Hair Care Products, Oil, Tea, Fish, Meat, Snack, Seasoning, Dairy Products |

| Type: | Automatic Labeling Machine |

| Driven Type: | Electric |

| Classification: | Automatic Vertical Round Bottle Labeling Machine |

| Customization: |

Available

| Customized Request |

|---|

What are the challenges associated with using plastic belts, and how can they be mitigated?

Using plastic belts in various applications comes with its own set of challenges. However, these challenges can be mitigated through various measures. Here’s a detailed explanation:

- 1. Temperature Limitations:

One of the challenges associated with plastic belts is their temperature limitations. Some plastic materials may have lower heat resistance compared to other belt materials like steel or rubber. In high-temperature environments, plastic belts may experience softening, deformation, or even melting, leading to a decrease in their performance and lifespan. To mitigate this challenge, it is important to select plastic belts with materials specifically designed to withstand the temperature range of the application. Additionally, incorporating cooling systems, such as ventilation or water cooling, can help maintain the belt’s temperature within acceptable limits.

- 2. Load Capacity:

Another challenge is the load capacity of plastic belts, particularly in heavy-duty applications. While plastic belts have been engineered to handle significant loads, there may be limitations compared to materials like steel or fabric-reinforced rubber belts. To mitigate this challenge, it is essential to carefully analyze the weight and characteristics of the conveyed materials and select plastic belts with appropriate load-carrying capacity. Reinforcement technologies, such as embedded fibers or metal cords, can be used to enhance the strength and load capacity of plastic belts for heavier applications.

- 3. Abrasion and Wear:

Plastic belts may face challenges related to abrasion and wear, especially in applications where materials with sharp edges or abrasive properties are being conveyed. Continuous contact with abrasive materials can cause premature wear and reduce the belt’s lifespan. To mitigate this challenge, plastic belts with enhanced wear resistance properties, such as specialized surface coatings or harder material formulations, can be used. Regular inspection and maintenance of the belts, including cleaning and proper tensioning, can also help identify and address any signs of wear before they become significant issues.

- 4. Chemical Compatibility:

In applications where plastic belts come into contact with chemicals or substances, compatibility with those chemicals can be a challenge. Certain chemicals may cause degradation or weakening of the belt material, leading to reduced performance or even failure. To mitigate this challenge, it is crucial to select plastic belts with materials that are chemically resistant to the specific substances encountered in the application. Conducting chemical compatibility tests and consulting with belt manufacturers can help ensure that the selected plastic belts can withstand the chemical environment they will be exposed to.

- 5. Belt Tracking and Alignment:

Plastic belts may face challenges related to tracking and alignment on the conveyor system. Misalignment can lead to increased friction, uneven wear, and potential damage to the belt and other conveyor components. To mitigate this challenge, proper belt tracking systems should be implemented, including precision tracking rollers, training idlers, or automated belt tracking mechanisms. Regular maintenance and inspection of the conveyor system can help identify and correct any issues with belt tracking and alignment before they cause significant problems.

- 6. Static Electricity:

Plastic belts can generate static electricity due to friction between the belt and the conveyed materials or the conveyor system. This static electricity can cause issues such as dust attraction, product sticking, or even electrical discharge hazards. To mitigate this challenge, anti-static additives or coatings can be incorporated into the belt material to dissipate static charges. Proper grounding of the conveyor system and the use of static eliminators, such as ionizers or grounding brushes, can also help minimize static electricity-related problems.

In summary, while there are challenges associated with using plastic belts, they can be effectively mitigated through appropriate measures. By carefully selecting belts with suitable temperature resistance, load capacity, and wear resistance, and implementing measures to address issues related to chemical compatibility, belt tracking, and static electricity, the challenges can be managed. Regular maintenance, inspection, and adherence to manufacturer guidelines are essential for ensuring the optimal performance and longevity of plastic belts in various applications.

What factors should be considered when selecting plastic belts for different industrial applications?

When selecting plastic belts for different industrial applications, several factors should be taken into consideration. Here are the key factors to consider:

- 1. Application Requirements:

Understand the specific requirements of the application. Consider factors such as the type of products being conveyed, the weight and size of the loads, the desired conveying speed, the operating temperature range, the presence of moisture or chemicals, and any special handling needs. Clear knowledge of the application requirements will help in selecting a plastic belt with the appropriate characteristics and capabilities.

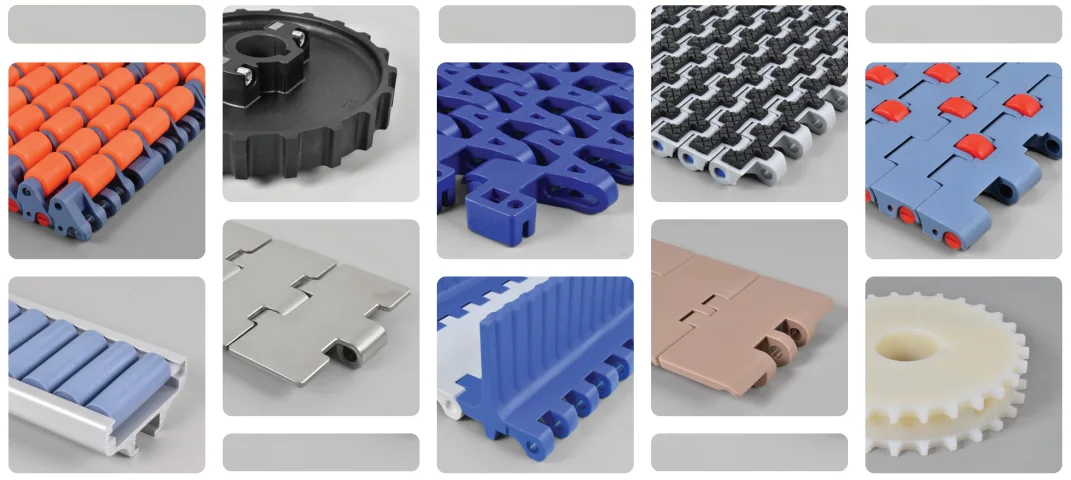

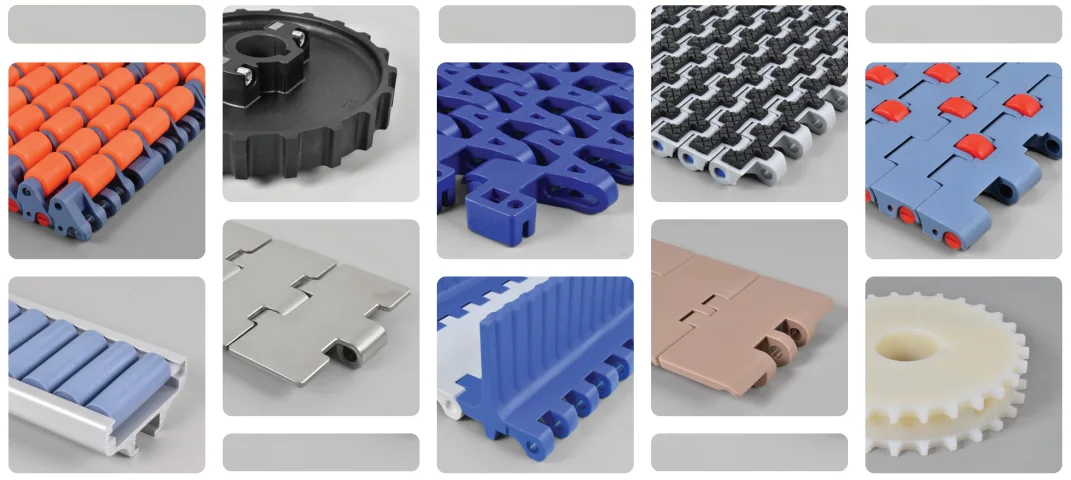

- 2. Belt Configuration and Design:

Consider the belt configuration and design that best suits the application. Different plastic belts come in various configurations, including flat-top, flush-grid, raised-rib, and modular designs. Evaluate the belt’s surface texture, open area percentage, and any specialized features such as cleats, perforations, or vacuum capabilities. The belt design should align with the product characteristics, conveying conditions, and any specific requirements like incline/decline conveying or product diverting.

- 3. Material Selection:

Choose the appropriate plastic material for the belt based on the application’s demands. Common plastic materials used for belts include polyethylene (PE), polypropylene (PP), acetal (POM), polyvinyl chloride (PVC), and polyurethane (PU). Consider factors such as chemical resistance, temperature resistance, wear resistance, flexibility, and food-grade compliance. Ensure the selected material can withstand the operating conditions and environmental factors that the belt will encounter.

- 4. Load Capacity and Durability:

Evaluate the load capacity requirements of the application and select a plastic belt that can handle the intended loads. Consider the weight capacity per unit width and the overall strength and durability of the belt. Factors such as the belt’s tensile strength, impact resistance, and resistance to abrasion or wear are important for ensuring the longevity and reliability of the belt in demanding industrial environments.

- 5. Cleanability and Hygiene:

In industries with stringent hygiene requirements, such as food processing or pharmaceuticals, prioritize plastic belts that are easy to clean and sanitize. Look for belts with smooth, non-porous surfaces that resist bacterial growth and are compatible with regular washdown procedures. Consider whether the belt can withstand cleaning agents and temperature variations without degradation or compromising its hygienic properties.

- 6. Compatibility with Conveyor System:

Ensure the selected plastic belt is compatible with the existing or planned conveyor system. Consider factors such as the belt’s width and length options, the type of conveyor system (e.g., flatbed, roller, or modular), the compatibility of the belt’s sprockets or pulleys with the conveyor system, and the ease of installation and maintenance. Proper compatibility will ensure smooth integration and optimal performance of the belt within the conveyor system.

- 7. Cost and Long-Term Value:

Evaluate the cost-effectiveness and long-term value of the plastic belt. Consider not only the upfront cost of the belt but also its expected lifespan, maintenance requirements, and potential savings in terms of reduced downtime, increased productivity, and lower operational costs. Balancing cost considerations with the desired performance and durability will help in selecting a plastic belt that delivers the best value for the specific industrial application.

By considering these factors in the selection process, industries can choose the most suitable plastic belt that meets the unique requirements of their industrial applications, ensuring efficient and reliable material handling operations.

Can you explain the advantages of using plastic belts over traditional materials in conveyor systems?

Using plastic belts in conveyor systems offers several advantages over traditional materials such as rubber or fabric. Plastic belts, also known as polymer belts or synthetic belts, are made from various types of plastic materials and provide unique characteristics that make them desirable for conveyor applications. Here’s a detailed explanation of the advantages of using plastic belts over traditional materials in conveyor systems:

- Durability and Longevity:

- Versatility and Customization:

- Hygienic and Easy to Clean:

- Low Friction and Energy Efficiency:

- Chemical Resistance:

- Lightweight and Easy Installation:

Plastic belts are known for their durability and longevity. They are resistant to wear, abrasion, and impact, allowing them to withstand harsh operating conditions. Unlike rubber or fabric belts, plastic belts do not easily degrade or stretch over time. They can handle heavy loads and maintain their shape and performance for extended periods, resulting in reduced maintenance and replacement costs for conveyor systems.

Plastic belts offer versatility and customization options for conveyor systems. They can be manufactured in various sizes, widths, and configurations to meet specific application requirements. Plastic belts can have different surface patterns, such as smooth, textured, or perforated, providing enhanced grip, airflow, or product release capabilities. Additionally, plastic belts can be designed with specialized features like high temperature resistance, chemical resistance, or anti-static properties, making them suitable for diverse industries and conveyor applications.

Plastic belts are highly hygienic and easy to clean, making them ideal for industries with strict cleanliness and sanitation standards. Unlike fabric belts, plastic belts do not absorb liquids or harbor bacteria, reducing the risk of contamination in food processing, pharmaceutical, or other clean environments. Plastic belts can be easily cleaned using water, steam, or cleaning agents, ensuring optimal hygiene and compliance with industry regulations.

Plastic belts offer low friction characteristics, resulting in energy-efficient conveyor systems. The reduced friction between the belt and the conveyor components minimizes power consumption, allowing for cost savings and environmental benefits. Additionally, the low friction properties of plastic belts contribute to smoother and quieter operation, reducing noise levels in the workplace.

Plastic belts exhibit excellent chemical resistance, making them suitable for conveyor systems that handle corrosive or aggressive substances. They can withstand exposure to various chemicals, oils, solvents, and cleaning agents without deteriorating or experiencing significant damage. Plastic belts’ chemical resistance ensures their longevity and reliability in industries such as chemical processing, pharmaceuticals, or wastewater treatment.

Plastic belts are lightweight compared to traditional materials, facilitating easy installation and maintenance of conveyor systems. The reduced weight of plastic belts reduces the strain on conveyor components, extending their lifespan. Additionally, the lightweight nature of plastic belts simplifies handling during installation or replacement, improving efficiency and reducing downtime.

In summary, using plastic belts in conveyor systems offers significant advantages over traditional materials. They provide durability, versatility, and customization options, ensuring long-lasting and efficient performance. Plastic belts are hygienic, easy to clean, and resistant to chemicals, making them suitable for industries with strict cleanliness requirements. They offer low friction and energy efficiency, contributing to cost savings and environmental benefits. Moreover, plastic belts are lightweight and easy to install, simplifying maintenance and reducing downtime. These advantages make plastic belts a preferred choice in various industries for their conveyor system needs.

editor by CX 2024-02-09