Product Description

1. More than10 years manufacture in packing machine

2. 10 years alibaba supplier

3. 100% QC inspection before shipment

4. 12 months warranty

5. Product Certificated by CE

Introduction:

ARLM-160A Automatic Labeling Machine can meet the needs of semi circle labeling, bottle labeling switching between simple, convenient adjustment;

Wide application range: self-adhesive labels, adhesive film, electronic monitoring code, bar code etc..

Application Industry: widely used in food, medicine, cosmetics, daily chemical, electronics, hardware, plastics and other industries.

Application example: PET round bottle labeling, plastic bottle labeling, canned food, etc.

Features:

1. Labeling quality, using standard of spring cover belt, labeling smooth, no wrinkles, improve packaging quality.

2. Flexible application, bottle stand vertical labeling, with automatic sub bottle function, can be stand-alone production, can also be connected to the production line.

3. Intelligent control, automatic photoelectric tracking, with no matter no labeling, no standard automatic calibration and label automatic detection function, prevent leakage and label waste.

4. Simple adjustment, labeling speed, conveying speed, bottle speed can be achieved stepless speed regulation, according to the need to adjust.

5. Durable, using 3 bar adjustment mechanism, make full use of triangular stability, solid durable machine. Made of stainless steel and advanced aluminum alloy, accord with CE Production requirements.

Customized Functions:

1. Can add coding,printing

2. The conveyor can be replaced with a chain plate

3. The width,length,hight can be customize

4. The custom function is applicable to all automatic labeling machines

5. The machine can only be used to sticker labels, can be customized to stick transparent labels, need to change the optical fiber to transparent optical fiber.(Conventional label by induction color; Transparent label by induction thickness)

Note:

This machine is standard machine, can only be used normal round bottles , can not be too soft or bulge.

Can be customized if the bottle has grooves.

Parameter:

| Model | ARLM-160A |

| Power | 550W |

| Filling speed | 10-50PCS/min |

| Filling accuracy | ±1% |

| Bottle diameter | 30-150mm |

| Bottle high | 10-500mm |

| Lable Weight | 20-150mm |

| Lable Hight | 30-160mm |

Q: Are you a factory or a trading company?

A: We are factory manufacturing packaging machines and weprovide perfect OEM and after-sale service.

Q: Can you send me the video to show how the machine works?

A: Certainly, we have made video of every machine and uploaded them to Youtube.

Q: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you.

Q: How can I know your machine is designed for my product?

A: You can send us samples of your product and we test it on machine.

Q: How can I pay my order?

A: We accept T/T, L/C paying methods. For those orders less than 500USD, we accept Trade Assurance to pay.

Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.

Your Satisfaction is Our Honor

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Automatic Grade: | Automatic |

|---|---|

| Applicable Industry: | Food, Cosmetics, Agriculture, Medicine, Daily Chem |

| Application: | Cosmetics, Drinks, Cleaning, Detergent, Skin Care Products, Hair Care Products, Oil, Tea, Fish, Meat, Snack, Seasoning, Dairy Products |

| Type: | Automatic Labeling Machine |

| Driven Type: | Electric |

| Classification: | Automatic Vertical Round Bottle Labeling Machine |

| Customization: |

Available

| Customized Request |

|---|

What are the challenges associated with using plastic belts, and how can they be mitigated?

Using plastic belts in various applications comes with its own set of challenges. However, these challenges can be mitigated through various measures. Here’s a detailed explanation:

- 1. Temperature Limitations:

One of the challenges associated with plastic belts is their temperature limitations. Some plastic materials may have lower heat resistance compared to other belt materials like steel or rubber. In high-temperature environments, plastic belts may experience softening, deformation, or even melting, leading to a decrease in their performance and lifespan. To mitigate this challenge, it is important to select plastic belts with materials specifically designed to withstand the temperature range of the application. Additionally, incorporating cooling systems, such as ventilation or water cooling, can help maintain the belt’s temperature within acceptable limits.

- 2. Load Capacity:

Another challenge is the load capacity of plastic belts, particularly in heavy-duty applications. While plastic belts have been engineered to handle significant loads, there may be limitations compared to materials like steel or fabric-reinforced rubber belts. To mitigate this challenge, it is essential to carefully analyze the weight and characteristics of the conveyed materials and select plastic belts with appropriate load-carrying capacity. Reinforcement technologies, such as embedded fibers or metal cords, can be used to enhance the strength and load capacity of plastic belts for heavier applications.

- 3. Abrasion and Wear:

Plastic belts may face challenges related to abrasion and wear, especially in applications where materials with sharp edges or abrasive properties are being conveyed. Continuous contact with abrasive materials can cause premature wear and reduce the belt’s lifespan. To mitigate this challenge, plastic belts with enhanced wear resistance properties, such as specialized surface coatings or harder material formulations, can be used. Regular inspection and maintenance of the belts, including cleaning and proper tensioning, can also help identify and address any signs of wear before they become significant issues.

- 4. Chemical Compatibility:

In applications where plastic belts come into contact with chemicals or substances, compatibility with those chemicals can be a challenge. Certain chemicals may cause degradation or weakening of the belt material, leading to reduced performance or even failure. To mitigate this challenge, it is crucial to select plastic belts with materials that are chemically resistant to the specific substances encountered in the application. Conducting chemical compatibility tests and consulting with belt manufacturers can help ensure that the selected plastic belts can withstand the chemical environment they will be exposed to.

- 5. Belt Tracking and Alignment:

Plastic belts may face challenges related to tracking and alignment on the conveyor system. Misalignment can lead to increased friction, uneven wear, and potential damage to the belt and other conveyor components. To mitigate this challenge, proper belt tracking systems should be implemented, including precision tracking rollers, training idlers, or automated belt tracking mechanisms. Regular maintenance and inspection of the conveyor system can help identify and correct any issues with belt tracking and alignment before they cause significant problems.

- 6. Static Electricity:

Plastic belts can generate static electricity due to friction between the belt and the conveyed materials or the conveyor system. This static electricity can cause issues such as dust attraction, product sticking, or even electrical discharge hazards. To mitigate this challenge, anti-static additives or coatings can be incorporated into the belt material to dissipate static charges. Proper grounding of the conveyor system and the use of static eliminators, such as ionizers or grounding brushes, can also help minimize static electricity-related problems.

In summary, while there are challenges associated with using plastic belts, they can be effectively mitigated through appropriate measures. By carefully selecting belts with suitable temperature resistance, load capacity, and wear resistance, and implementing measures to address issues related to chemical compatibility, belt tracking, and static electricity, the challenges can be managed. Regular maintenance, inspection, and adherence to manufacturer guidelines are essential for ensuring the optimal performance and longevity of plastic belts in various applications.

Can plastic belts be customized for specific industries or conveyor configurations?

Yes, plastic belts can be customized to meet the specific requirements of different industries or conveyor configurations. Here’s a detailed explanation:

- 1. Industry-Specific Customization:

Plastic belt manufacturers understand that different industries have unique needs and operating conditions. Therefore, they offer customization options to tailor plastic belts to specific industry requirements. For example:

- In the food industry, plastic belts can be customized to meet stringent hygiene standards, such as having smooth surfaces for easy cleaning, being made from food-grade materials, or incorporating features like detectable materials for food safety.

- In the automotive industry, plastic belts can be customized to withstand high temperatures, resist oil and grease, and have enhanced durability to handle heavy loads.

- In the pharmaceutical industry, plastic belts can be customized to be resistant to chemicals, moisture, and microbial growth, ensuring compliance with strict regulatory requirements.

- In the packaging industry, plastic belts can be customized to have specific surface textures or patterns for efficient product transfer, or they can be designed with specialized attachments for precise product positioning or diverting.

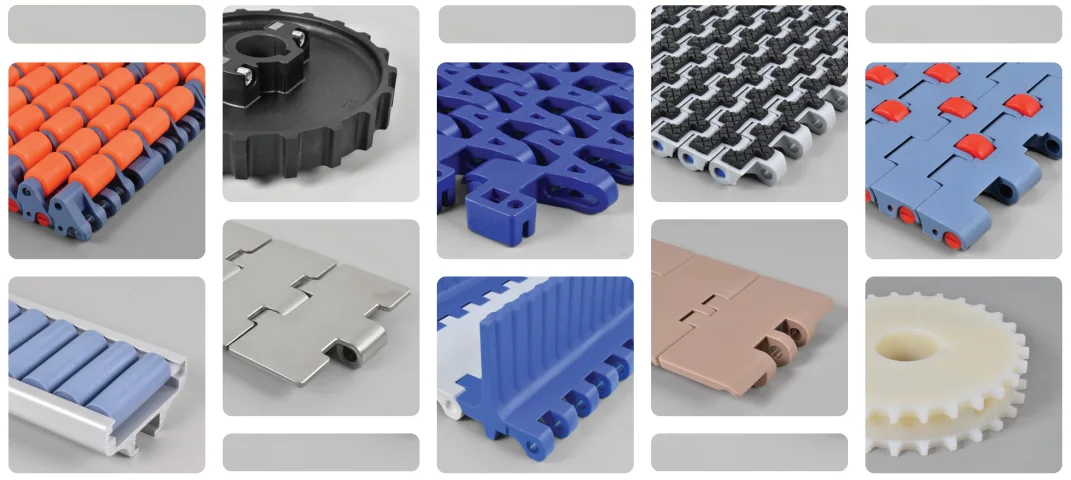

- 2. Conveyor Configuration Customization:

Plastic belts can also be customized to match the specific conveyor configurations and requirements of individual applications. Conveyor systems come in various types, such as flatbed, roller, or modular conveyors, and may have unique characteristics or dimensions. Plastic belt manufacturers offer customization options to ensure a seamless fit with the conveyor system, including:

- Customized belt widths and lengths to match the dimensions of the conveyor system.

- Specialized belt designs, such as flat-top, flush-grid, or raised-rib configurations, based on the conveyor’s requirements for product stability, grip, or drainage.

- Customized belt accessories, such as sprockets, pulleys, or cleats, designed to work seamlessly with the conveyor system and provide the desired functionality.

- Modular plastic belts that can be easily assembled or reconfigured to fit different conveyor layouts or accommodate specific product handling needs.

Through industry-specific customization and conveyor configuration customization, plastic belts can be tailored to address the unique challenges and requirements of various industries and conveyor systems. This level of customization ensures optimal performance, efficiency, and reliability in material handling operations.

Can you describe the different types of plastic belts available in the market today?

There are several different types of plastic belts available in the market today, each designed to meet specific application requirements. Here’s an overview of some commonly used types:

- 1. Modular Plastic Belts:

Modular plastic belts consist of interlocking plastic modules or links that form a continuous belt. These belts offer flexibility, allowing them to navigate around corners, bends, and other obstacles smoothly. They are commonly used in applications that require accumulation, incline/decline conveying, or small product transfer. Modular plastic belts are available in various configurations, such as flat-top, flush-grid, and raised-rib designs, to accommodate different product types and handling requirements.

- 2. Solid Plastic Belts:

Solid plastic belts are made from a single piece of plastic material without interlocking modules. They offer a smooth and continuous surface, making them suitable for applications that require stable and consistent product conveying. Solid plastic belts are often used in industries such as food processing, where hygiene, easy cleaning, and resistance to contamination are crucial.

- 3. Cleated Plastic Belts:

Cleated plastic belts feature integrally molded cleats or projections on their surface. These cleats help to prevent product slippage and facilitate the inclined or vertical movement of bulk materials or packages. Cleated plastic belts are commonly used in applications such as incline or decline conveying, sorting, and elevating products in industries like agriculture, recycling, and manufacturing.

- 4. Wire Mesh Plastic Belts:

Wire mesh plastic belts consist of a plastic mesh overlaying metal or plastic rods. These belts offer an open and breathable surface, allowing for easy drainage, airflow, and visual inspection of conveyed products. They are often used in applications where heat, steam, or liquids need to pass through the belt, such as baking ovens, washing processes, or drying operations in the food industry.

- 5. Vacuum Plastic Belts:

Vacuum plastic belts are designed with a perforated or porous surface that allows the application of vacuum pressure to hold and stabilize lightweight or delicate products during conveying. These belts are commonly used in industries such as electronics, printing, and packaging, where precise positioning and gentle handling of products are required.

- 6. Anti-Static Plastic Belts:

Anti-static plastic belts are specifically designed to dissipate static electricity and prevent the buildup of electrostatic charges. They are used in applications where static discharge could damage sensitive electronic components or create safety hazards. Anti-static plastic belts are commonly employed in electronics manufacturing, semiconductor production, and cleanroom environments.

These are just a few examples of the different types of plastic belts available in the market today. The choice of plastic belt depends on factors such as the application requirements, load capacity, product characteristics, environmental conditions, and industry-specific regulations. Manufacturers often offer a range of customization options to tailor the belt design, material, and features to meet the specific needs of their customers.

editor by CX 2024-02-24

China high quality Hzpk Arlm-160A China Labeler Food Cans Cosmetic Jar Labeling Machine axle bolt

Product Description

1. More than10 years manufacture in packing machine

2. 10 years alibaba supplier

3. 100% QC inspection before shipment

4. 12 months warranty

5. Product Certificated by CE

Introduction:

ARLM-160A Automatic Labeling Machine can meet the needs of semi circle labeling, bottle labeling switching between simple, convenient adjustment;

Wide application range: self-adhesive labels, adhesive film, electronic monitoring code, bar code etc..

Application Industry: widely used in food, medicine, cosmetics, daily chemical, electronics, hardware, plastics and other industries.

Application example: PET round bottle labeling, plastic bottle labeling, canned food, etc.

Features:

1. Labeling quality, using standard of spring cover belt, labeling smooth, no wrinkles, improve packaging quality.

2. Flexible application, bottle stand vertical labeling, with automatic sub bottle function, can be stand-alone production, can also be connected to the production line.

3. Intelligent control, automatic photoelectric tracking, with no matter no labeling, no standard automatic calibration and label automatic detection function, prevent leakage and label waste.

4. Simple adjustment, labeling speed, conveying speed, bottle speed can be achieved stepless speed regulation, according to the need to adjust.

5. Durable, using 3 bar adjustment mechanism, make full use of triangular stability, solid durable machine. Made of stainless steel and advanced aluminum alloy, accord with CE Production requirements.

Customized Functions:

1. Can add coding,printing

2. The conveyor can be replaced with a chain plate

3. The width,length,hight can be customize

4. The custom function is applicable to all automatic labeling machines

5. The machine can only be used to sticker labels, can be customized to stick transparent labels, need to change the optical fiber to transparent optical fiber.(Conventional label by induction color; Transparent label by induction thickness)

Note:

This machine is standard machine, can only be used normal round bottles , can not be too soft or bulge.

Can be customized if the bottle has grooves.

Parameter:

| Model | ARLM-160A |

| Power | 550W |

| Filling speed | 10-50PCS/min |

| Filling accuracy | ±1% |

| Bottle diameter | 30-150mm |

| Bottle high | 10-500mm |

| Lable Weight | 20-150mm |

| Lable Hight | 30-160mm |

Q: Are you a factory or a trading company?

A: We are factory manufacturing packaging machines and weprovide perfect OEM and after-sale service.

Q: Can you send me the video to show how the machine works?

A: Certainly, we have made video of every machine and uploaded them to Youtube.

Q: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you.

Q: How can I know your machine is designed for my product?

A: You can send us samples of your product and we test it on machine.

Q: How can I pay my order?

A: We accept T/T, L/C paying methods. For those orders less than 500USD, we accept Trade Assurance to pay.

Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.

Your Satisfaction is Our Honor

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Automatic Grade: | Automatic |

|---|---|

| Applicable Industry: | Food, Cosmetics, Agriculture, Medicine, Daily Chem |

| Application: | Cosmetics, Drinks, Cleaning, Detergent, Skin Care Products, Hair Care Products, Oil, Tea, Fish, Meat, Snack, Seasoning, Dairy Products |

| Type: | Automatic Labeling Machine |

| Driven Type: | Electric |

| Classification: | Automatic Vertical Round Bottle Labeling Machine |

| Customization: |

Available

| Customized Request |

|---|

Can you explain the impact of temperature and chemical exposure on plastic belt performance?

The impact of temperature and chemical exposure on plastic belt performance is significant. Here’s a detailed explanation:

- Temperature:

Temperature can have both immediate and long-term effects on plastic belt performance. Extreme temperatures can cause plastic belts to undergo physical changes that affect their structural integrity and functionality. Here are the impacts of temperature:

- High Temperatures:

Exposure to high temperatures can cause plastic belts to soften or deform. This softening can lead to belt elongation, loss of tension, and reduced load-carrying capacity. In extreme cases, the belt may become misaligned or even melt, resulting in operational disruptions and potential damage to the conveyor system. It’s crucial to select plastic belts that can withstand the elevated temperatures of the application to ensure reliable performance and prevent premature failure.

- Low Temperatures:

Low temperatures can make plastic belts more brittle and susceptible to cracking or breakage. The reduced flexibility of the belt material can lead to increased stress concentrations, especially in areas with sharp bends or high impact loads. Brittle belts are more prone to damage during operation, which can result in belt failure and system downtime. Choosing plastic belts specifically designed for low-temperature environments or implementing insulation measures can help mitigate the negative impact of cold temperatures on belt performance.

- Chemical Exposure:

Chemical exposure can significantly affect plastic belt performance, depending on the type and concentration of chemicals involved. Plastic belts can experience various forms of chemical degradation, including:

- Chemical Attack:

Some chemicals can react with the plastic material, causing it to break down or degrade. This chemical attack can result in the loss of material strength, increased brittleness, or changes in the belt’s physical properties. The severity of chemical attack depends on the specific chemical composition of the belt and the nature and concentration of the chemicals it comes into contact with. It’s crucial to select plastic belts with appropriate chemical resistance properties based on the application’s chemical environment.

- Swelling or Dissolution:

Certain chemicals can cause plastic belts to swell or dissolve. Swelling occurs when the belt absorbs the chemical, leading to dimensional changes and potential belt misalignment. Dissolution happens when the chemical breaks down the plastic material, resulting in loss of belt structure and strength. Swelling and dissolution can compromise the integrity of the belt and its ability to perform effectively. Choosing plastic belts with resistance to the specific chemicals present in the application is essential to prevent these issues.

- Surface Damage:

Chemical exposure can also cause surface damage to plastic belts. Some chemicals may cause staining, discoloration, or surface roughness, which can impact the belt’s appearance and potentially affect its functionality. Additionally, chemicals with abrasive properties can cause physical wear and tear on the belt surface, reducing its lifespan and increasing the risk of belt failure. Regular inspection and prompt replacement of chemically damaged belts are necessary to maintain optimal performance and prevent potential contamination of the conveyed products.

In summary, temperature and chemical exposure have significant impacts on plastic belt performance. Extreme temperatures can lead to softening, deformation, or brittleness of the belt material, affecting its structural integrity and load-carrying capacity. Chemical exposure can cause chemical attack, swelling, dissolution, or surface damage, compromising the belt’s strength, dimensional stability, and overall functionality. Selecting plastic belts designed for the specific temperature range and chemical environment of the application, along with regular inspection and maintenance, is crucial to ensure reliable and long-lasting performance of plastic belts in conveyor systems.

What role do plastic belts play in ensuring hygiene and cleanliness in food processing applications?

Plastic belts play a crucial role in ensuring hygiene and cleanliness in food processing applications. Here’s a detailed explanation:

- 1. Smooth, Non-Porous Surfaces:

Plastic belts used in food processing applications are designed with smooth, non-porous surfaces. These surfaces prevent the accumulation of food particles, liquids, or other contaminants, reducing the risk of bacterial growth and cross-contamination. Smooth surfaces also make it easier to clean the belts effectively, ensuring optimal hygiene standards are maintained.

- 2. Resistance to Moisture and Chemicals:

Plastic belts for food processing applications are resistant to moisture and a wide range of chemicals used in cleaning and sanitization processes. They can withstand frequent washdowns with water, detergents, and disinfectants without degrading or compromising their structural integrity. This resistance to moisture and chemicals contributes to the overall cleanliness and hygiene of the food processing environment.

- 3. Bacterial Growth Prevention:

Plastic belts inhibit bacterial growth due to their non-porous surfaces and resistance to moisture. Unlike fabric belts, which can absorb and retain moisture, plastic belts do not provide a favorable environment for bacteria to thrive. By minimizing bacterial growth, plastic belts help maintain the cleanliness and safety of food products during processing.

- 4. Compatibility with Sanitization Processes:

Plastic belts used in food processing applications are designed to withstand regular sanitization procedures. They can be easily cleaned using standard cleaning agents, high-pressure washdowns, or even steam cleaning. Plastic belts are resilient to the harsh chemicals and high temperatures often employed in food processing facilities for effective sanitization, ensuring that the belts themselves remain hygienic and do not become a source of contamination.

- 5. Compliance with Food Safety Standards:

Plastic belts used in the food processing industry are often manufactured from food-grade materials that comply with relevant safety regulations. These materials are chosen for their ability to meet strict food safety requirements, including FDA (Food and Drug Administration) or EU (European Union) regulations. By using plastic belts that meet these standards, food processors can ensure that their operations align with the necessary hygiene and safety guidelines.

- 6. Easy Maintenance and Inspection:

Plastic belts are relatively easy to maintain and inspect for cleanliness. Their smooth surfaces allow for quick visual inspection to detect any visible contamination or debris. If cleaning is required, plastic belts can be easily cleaned using appropriate methods, reducing downtime and allowing for efficient production processes.

In summary, plastic belts play a vital role in ensuring hygiene and cleanliness in food processing applications. Their smooth, non-porous surfaces, resistance to moisture and chemicals, prevention of bacterial growth, compatibility with sanitization processes, compliance with food safety standards, and ease of maintenance contribute to maintaining a clean and safe environment for food processing operations.

What are plastic belts, and how are they used in various industries?

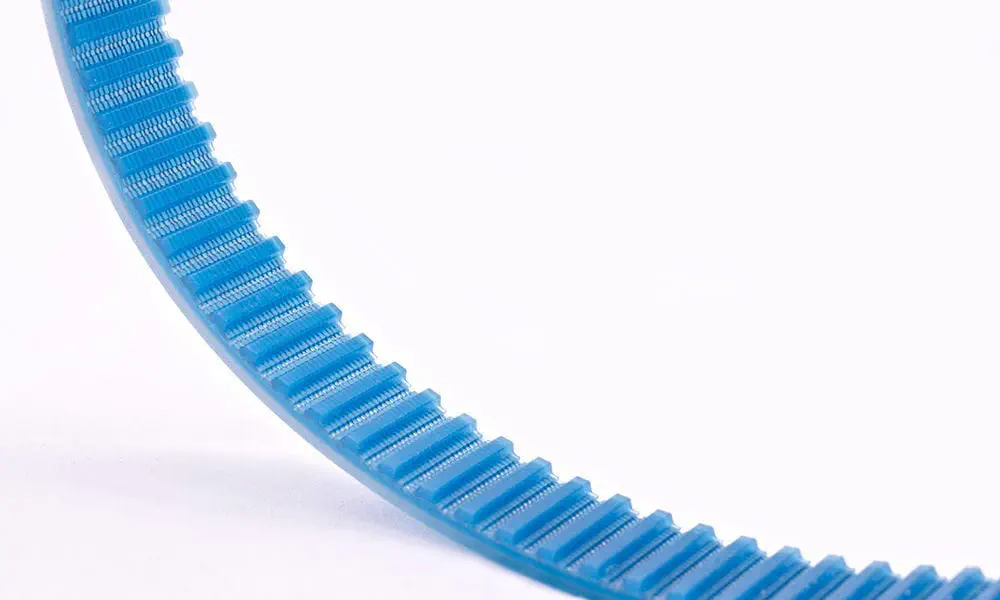

Plastic belts, also known as polymer belts or synthetic belts, are conveyor belts made from various types of plastic materials. These belts are used in a wide range of industries for conveying, transporting, or processing materials or products. Plastic belts offer several advantages over traditional belt materials such as rubber or fabric, including durability, versatility, and ease of maintenance. Here’s a detailed explanation of plastic belts and their applications in various industries:

- Composition and Construction:

- Food and Beverage Industry:

- Automotive Industry:

- Packaging and Logistics:

- Agriculture and Horticulture:

- Other Industries:

Plastic belts are typically made from materials such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polyurethane (PU), or acetal (POM). These materials provide properties such as high strength, chemical resistance, low friction, and flexibility. Plastic belts are manufactured through processes like extrusion, injection molding, or bonding, resulting in a wide variety of belt types, including flat belts, modular belts, timing belts, and conveyor chains.

Plastic belts find extensive use in the food and beverage industry. They are employed in applications such as food processing, packaging, sorting, and transportation. Plastic belts are preferred in these industries due to their hygienic properties, resistance to moisture and chemicals, and ease of cleaning. They are commonly used in conveying and sorting systems for products like fruits, vegetables, baked goods, meat, poultry, and beverages.

In the automotive industry, plastic belts are utilized for various purposes. They are employed in assembly lines for transporting automotive components during the manufacturing process. Plastic belts with specialized features, such as high temperature resistance or static dissipation properties, are used in applications like paint shops, heat treatment processes, or electrostatic discharge-sensitive areas. Plastic belts provide reliable and efficient material handling solutions in automotive production facilities.

Plastic belts play a crucial role in packaging and logistics operations. They are used in conveyor systems for handling packages, cartons, boxes, or containers in industries such as e-commerce, retail, distribution centers, and postal services. Plastic belts offer smooth and reliable transportation, enabling efficient sorting, merging, diverging, and accumulation of items. Their flexibility and customization options make them suitable for a wide range of packaging and logistics applications.

In the agriculture and horticulture industries, plastic belts are employed for tasks like seed sorting, crop harvesting, and greenhouse operations. Plastic belts with specialized features like perforations or airflow patterns are used to facilitate the handling and processing of seeds, fruits, vegetables, or flowers. They provide gentle and efficient transportation, reducing damage to delicate agricultural products and improving productivity in these sectors.

Plastic belts find applications in various other industries as well. They are used in industries such as pharmaceuticals, electronics, textile manufacturing, recycling, and airport baggage handling. Plastic belts offer advantages like chemical resistance, anti-static properties, and low noise levels, making them suitable for specific requirements in these industries.

In summary, plastic belts are conveyor belts made from plastic materials and are widely used in various industries. They offer durability, versatility, and ease of maintenance, making them suitable for applications in food and beverage processing, automotive manufacturing, packaging and logistics, agriculture and horticulture, and many other sectors. Plastic belts provide efficient material handling solutions, ensuring smooth transportation, sorting, and processing of products or materials in diverse industrial settings.

editor by CX 2024-01-11

China Professional Industrial Supplier High Speed Paper Machine Driving Narrow V Belt for Vietnam Food and Printing Industry with Free Design Custom

Merchandise Description

OUR Companions

Solution: Tiger Industrial Supplier Substantial Pace Paper Machine Driving Slender V Belt for Vietnam Foods and Printing Industry SPZ1164/3V460

Specialized DATAS

Apps

PAYMENT Strategies

T/T, Western Union, Moneygram are current conditions.

WHY Decide on US

High quality ASSURANCE

Ensure that the commodity hereof complies in all respects with the high quality and specification stipulated in the deal.

Supply Guarantee

Ship the items in the cargo time from the port of shipment to the location in the contract.

Manufacturing unit Price

Costs refer to the value of uncooked resources immediately from manufacturing unit.

Crew OF Professionals

Provide seasoned buyer support and specialized assist such as belts assortment, calculation, software and following-sale services.

FABRICATION WORKSHOP

Supply belts cutting, jointing, as nicely as belt perforations, belt sealed, belt coated with rubber and sponge, belt guides, and many others.

Support Community

Set up business office, branches in HangZhou, HangZhou, HangZhou, Hongkong, etc, provider locations for processing industrial belts in HangZhou, HangZhou, Yongbo etc.

ABOUT US

Overview

Firm Introductio

Our Merchandise

Production and Processing

Test Report

OTHER Relevant Items

-device tape

-spindle tape

-tangential travel belt

-OE rotor spinning belt

-twisting flat belt

-folder-gluer belt

-extruded spherical belt polycord

-conveyor processing belt

How to Avert Timing Belt Difficulties

Not like their predecessors, timing chains and timing belts are created of rubber and synchronize the opening and closing of valves in the motor. Although their benefits are several, they are prone to use and tear above time. Listed here are some ideas for making certain your timing belt lasts for several several years. Outlined under are some of the most widespread difficulties that you may face when shifting your timing belt. Go through on to discover out how to prevent them and hold your automobile managing at peak functionality.

Timing belts are rubber

There are a lot of positive aspects to making use of timing belts in your auto. They are lightweight and reduce the pressure on your vehicle’s internal parts. They are also peaceful when working, so you won’t have to hear to your car to know that servicing is required. If you are anxious about sound, a quiet engine can aid you establish no matter whether your timing belts are damaged or if you need to replace them entirely. A peaceful engine can also support you notice indications of dress in and tear before you do.

No matter of content, rubber timing belts can be inclined to stretching and breaking. They also are inclined to higher temperatures and the lubrication of motor oil, minimizing their lifespan. Manufacturers have responded to this problem by producing timing belts created of engine-temperature-resistant rubber resources. The improved rubber compounds also offer higher energy and resistance to distortion. Reinforcing fibers also shield the tooth from shearing, decreasing the risk of a worn-out timing belt.

Whilst the open up-ended, or spliced, varieties of timing belts have several benefits, they are normally unsuitable for substantial-pace apps. In most circumstances, rubber timing belts are utilized in substantial-velocity device tools and automatic doors. They are also peaceful and need nominal upkeep. These attributes make rubber timing belts a excellent option for higher-pace apps. You can even get custom made-created timing belts for uncommon applications.

Timing belts are important for the functioning of an engine. They website link the camshaft and crankshaft to the crankshaft. They manage the motion of valves and pistons. If a timing belt fails, it can cause major damage to the engine. If you are doubtful of the benefits of rubber timing belts, take into account a movie on the topic. This will provide you with far more information on timing belts.

They synchronize the opening and closing of the engine’s valves

For the duration of the combustion process of the engine, the valves in the cylinder head open up and near. Clean air enters the cylinder, which burns with the gasoline to generate electricity. Exhaust escapes the motor through the exhaust valve. Every single cylinder contains between two and 4 valves. The timing belt drives a camshaft, which rotates in a precise way to synchronize the valve opening and closing.

A timing belt is a toothed rubber belt that connects the engine’s crankshaft to the crankshaft. Like most rubber areas, timing belts degrade over time, so it’s essential to change them at the proper intervals. Alternative intervals vary relying on the make and design of the automobile, but they need to be changed each sixty to ninety thousand miles.

A damaged timing belt will not start off the engine. A timing belt driven automobile will require to be towed to a restore shop for repairs. In the automotive industry, timing belts travel the two “cost-free running” and “interference” engines. The timing belt transfers the crankshaft’s rotation to the camshafts, which in switch actuate the valves in the intake and exhaust method. When they malfunction, the pistons can speak to open valves, bending or punching them.

Timing belts also work with pistons and connecting rods to generate power. Excellent timing is vital for the engine to run easily. The timing belt regulates both the pistons and the valves. If they are out of sync, they may not ignite correctly, major to catastrophic motor failure. When you are searching for a substitution, search for these indicators of put on.

They are lighter, quieter and far more productive than timing chains

While the preliminary decision was for quieter overall performance, variable timing has led to increased performance and electrical power. Whilst sound is a element, the average buyer cannot tell the variation. And although timing belts are usually lighter and quieter, a chain can be far more noisy than a belt, which can lead to a lot more engine damage. If you happen to be unsure regardless of whether you ought to decide for a chain or a belt, consult your owner’s handbook.

A timing chain capabilities comparable to a timing belt but is made from steel and is housed inside the motor compartment. It gets its lubrication from motor oil. Timing chains can previous a extended time as long as you maintain them properly preserved. A timing chain is not as efficient as a timing belt, but it is much more precise, quieter and easier to maintain.

A timing belt makes use of teeth to time the motion of numerous elements in an engine. When the timing belt is damaged, the valves in the engine will not be in sync, foremost to a loss of pressure in the combustion chamber. This can lead to a plethora of motor problems and cost-growing repairs. A timing belt is also quieter and needs much less lubrication, so it is safer and quieter than a timing chain.

After the arrival of variable valve timing, cars began to use a timing chain. This design enhanced engine efficiency and reduced upkeep, but it also caused a backlash as consumers were no lengthier intrigued in this variety of routine servicing. Right now, even so, timing chains are generating a comeback in the automotive sector. Even though contemporary chains can still be noisy, they are simpler to preserve, are lighter, and last longer than their chain counterparts.

They put on out above time

Even the ideal drive belts will at some point dress in out. The major triggers of belt dress in consist of mileage and warmth. The belt bends as it passes the pulley, making warmth that hardens the rubber. When the belt slips, it boosts friction, accelerating the approach. A worn-out belt can be quite tough to start off, creating an engine to drop gas performance. To help prevent this issue, examine the belt for dress in and tear.

A timing belt is an motor element that connects the camshaft to the crankshaft and controls the timing of combustion. These belts are created of industrial-power rubber, and frequently have nylon-strengthened cords. Even though they are meant to last, they will sooner or later put on out. If the timing belt fails, your engine will not likely operate smoothly or you could devote hundreds of pounds fixing it.

A defective timing belt can cause the valves to open as well early or as well late, creating poor combustion and a drop in engine functionality. If the timing belt breaks, the valves may hit the pistons and result in harm. This can guide to engine breakage, which calls for a new motor. To stop this, you should substitute the timing belt each and every few of thousand miles. If you are unable to discover a reliable mechanic, it is greatest to seek out expert support from a respected mechanic.

An additional warning indicator that your timing belt demands replacing is a ticking seem coming from within your engine. This is an indicator of a lower oil stress than regular. Lower oil pressure can affect the timing belt as it can cause the tensioner that retains the belt taut will lose strain. Sooner or later, the belt may even crack, allowing the camshafts to slip and crack. As soon as this takes place, it is time to substitute the timing belt.

They can be fixed

Timing belts can be fixed. If your timing belt breaks, you can just take your auto to a mend store to have it repaired or replaced. The value of a fix relies upon on the labor several hours and how several hours it requires to do the task. A undesirable timing belt can destroy your motor and trigger it to crack down entirely. If you happen to be not able to generate your vehicle, it may need towing and a new engine.

For most drivers, a timing belt substitute will price about $1,000 at a dealership. Fortunately, you can usually get the exact same support for less at an impartial vehicle restore shop. Typically, a timing belt mend demands changing the water pump, way too. It helps make feeling to replace each at the identical time. But bear in mind that timing belts are more difficult than that. If you are concerned about the expense, you can replace the drinking water pump together with the timing belt.

If you are in the temper to do this repair, there are several businesses that offer you this support. The expense is reasonably lower and you will probably conserve hundreds of pounds above the system of the job. Nonetheless, timing belt fix is not a easy job and need to be done properly or you could finish up harmful your automobile engine. As a result, it truly is important to know how to fix a timing belt by yourself to steer clear of the large price of selecting a mechanic.

When timing belts commence to fall short, there are a number of warning symptoms you can hear for. A hard begin-up can be a sign that your belt wants to be replaced. Also, thick smoke coming from the tailpipe can be a signal that the timing belt wants to be altered. In addition to these symptoms, your timing belt may possibly have a crack or broken gear enamel, which signifies it demands to be replaced.